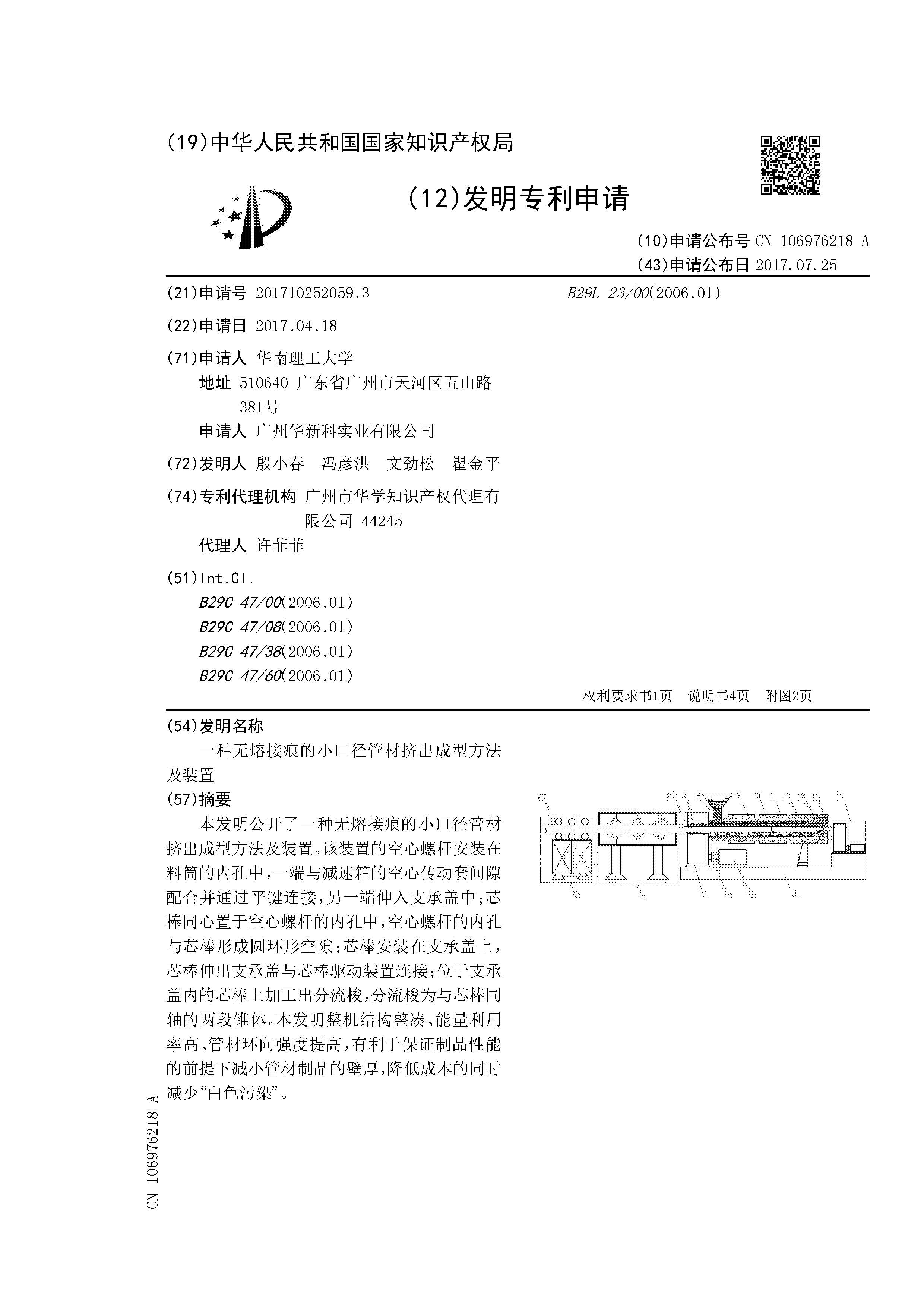

本发明公开了一种无熔接痕的小口径管材挤出成型方法及装置。该装置的空心螺杆安装在料筒的内孔中,一端与减速箱的空心传动套间隙配合并通过平键连接,另一端伸入支承盖中;芯棒同心置于空心螺杆的内孔中,空心螺杆的内孔与芯棒形成圆环形空隙;芯棒安装在支承盖上,芯棒伸出支承盖与芯棒驱动装置连接;位于支承盖内的芯棒上加工出分流梭,分流梭为与芯棒同轴的两段锥体。本发明整机结构整凑、能量利用率高、管材环向强度提高,有利于保证制品性能的前提下减小管材制品的壁厚,降低成本的同时减少“白色污染”。

The invention discloses a weld-mark-free small-caliber pipe extrusion forming method and device. According to the weld-mark-free small-caliber pipe extrusion forming device, a hollow threaded rod is installed in an inner hole of a material barrel, one end of the hollow threaded rod is in clearance fit with a hollow transmission sleeve of a reduction gearbox and connected with the hollow transmission sleeve of the reduction gearbox through a flat key, and the other end of the hollow threaded rod extends into a supporting cover; a core rod is concentrically arranged in an inner hole of the hollow threaded rod, and a circular-ring-shaped gap is formed between the inner hole of the hollow threaded rod and the core rod; the rod is installed on the supporting cover, the core rod extends out of the supporting cover and is connected with a core rod driving device; a spreader is machined on the portion, inside the supporting cover, of the core rod, and the spreader is two sections of cone bodies coaxial with the core rod. According to the weld-mark-free small-caliber pipe extrusion forming method and device, the overall structure is compact, the energy utilization rate is high, the annular strength of pipes is improved, on the premise of guaranteeing the performance of manufactured products, the wall thickness of the pipe products is reduced beneficially, cost is reduced, and white pollution is reduced at the same time.