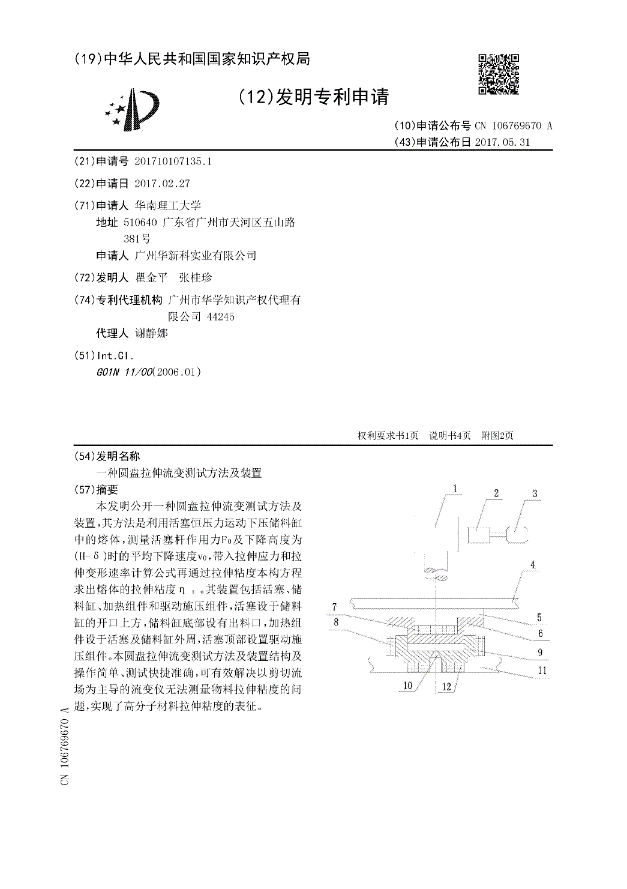

本发明公开一种圆盘拉伸流变测试方法及装置,其方法是利用活塞恒压力运动下压储料缸中的熔体,测量活塞杆作用力F0及下降高度为(H#δ)时的平均下降速度v0,带入拉伸应力和拉伸变形速率计算公式再通过拉伸粘度本构方程求出熔体的拉伸粘度ηε。其装置包括活塞、储料缸、加热组件和驱动施压组件,活塞设于储料缸的开口上方,储料缸底部设有出料口,加热组件设于活塞及储料缸外周,活塞顶部设置驱动施压组件。本圆盘拉伸流变测试方法及装置结构及操作简单、测试快捷准确,可有效解决以剪切流场为主导的流变仪无法测量物料拉伸粘度的问题,实现了高分子材料拉伸粘度的表征。

The invention discloses a method and a device for testing disk tensile rheology. The method comprises the following steps: pressing a melt in a material storage cylinder by utilizing constant-pressure motion of a piston; measuring a piston rod acting force F0 and an average descent velocity v0 when the descent height is (H-delta), and substituting the F0 and the v0 into a tensile stress and tensile deformation rate calculation formula; then solving the tensile viscosity eta epsilon of the melt through a tensile viscosity constitutive equation. The device comprises the piston, the material storage cylinder, heating assemblies and a driving and pressing assembly, wherein the piston is arranged above an opening of the material storage cylinder; a material outlet is formed in the bottom part of the material storage cylinder; the heating assemblies are arranged at the peripheries of the piston and the material storage cylinder; the driving and pressing assembly is arranged at the top part of the piston. The method and the device for testing the disk tensile rheology, disclosed by the invention, are simple in structure and operation and quick and accurate in testing, is capable of effectively solving the problem that the tensile viscosity of materials cannot be measured by a rheometer which takes a shear flow field as a main flow field, and representation of the tensile viscosity of high polymer materials is realized.