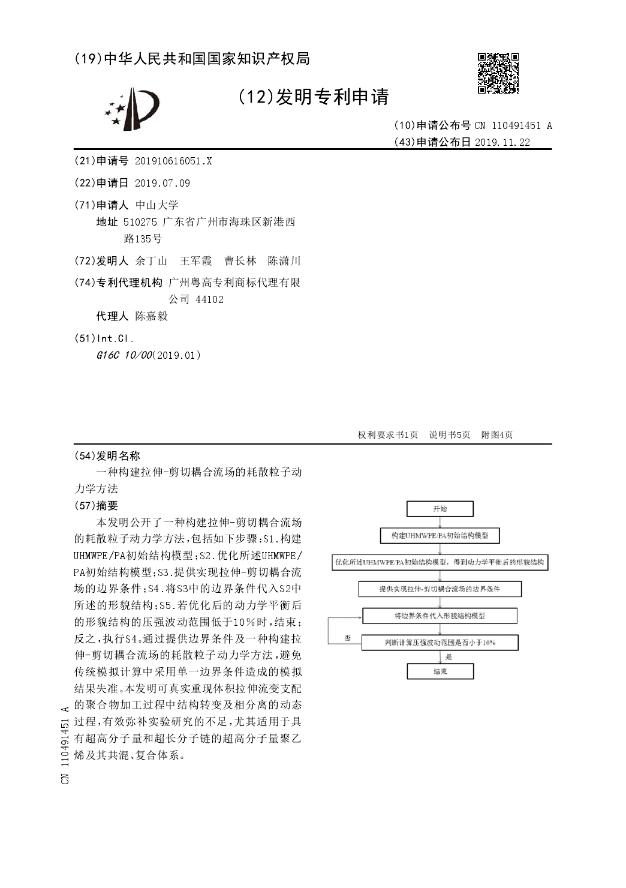

本发明公开了一种构建拉伸-剪切耦合流场的耗散粒子动力学方法,包括如下步骤:S1.构建UHMWPE/PA初始结构模型;S2.优化所述UHMWPE/PA初始结构模型;S3.提供实现拉伸-剪切耦合流场的边界条件;S4.将S3中的边界条件代入S2中所述的形貌结构;S5.若优化后的动力学平衡后的形貌结构的压强波动范围低于10%时,结束;反之,执行S4。通过提供边界条件及一种构建拉伸-剪切耦合流场的耗散粒子动力学方法,避免传统模拟计算中采用单一边界条件造成的模拟结果失准。本发明可真实重现体积拉伸流变支配的聚合物加工过程中结构转变及相分离的动态过程,有效弥补实验研究的不足,尤其适用于具有超高分子量和超长分子链的超高分子量聚乙烯及其共混、复合体系。

The invention discloses a dissipative particle dynamics method for building a tension-shear coupling flow field. The method comprises the following steps that S1, a UHMWPE/PA initial structure model is built; S2, the UHMWPE/PA initial structure model is optimized; S3, boundary conditions for achieving the tension-shear coupling flow field are provided; S4, the boundary conditions in S3 are substituted into a topographic structure in S2; S5, if the pressure fluctuation range of the optimized topographic structure after the dynamic equilibrium is less than 10%, the process ends, otherwise, S4 isexecuted. By providing the boundary conditions and the dissipative particle dynamics method for building the tension-shear coupling flow field, the phenomenon that due to the fact that in traditionalsimulating computation, single boundary conditions are adopted, simulation results are inaccurate is avoided. Accordingly, the dynamic process of structural transformation and phase separation in thevolume-stretched rheological control polymer processing can be truly reproduced, the defects of experiment research are effectively overcome, and the method is particularly applicable to ultra-high molecular weight polyethylene with ultra-high molecular weights and ultra-long molecular chains and blending and compounding systems thereof.