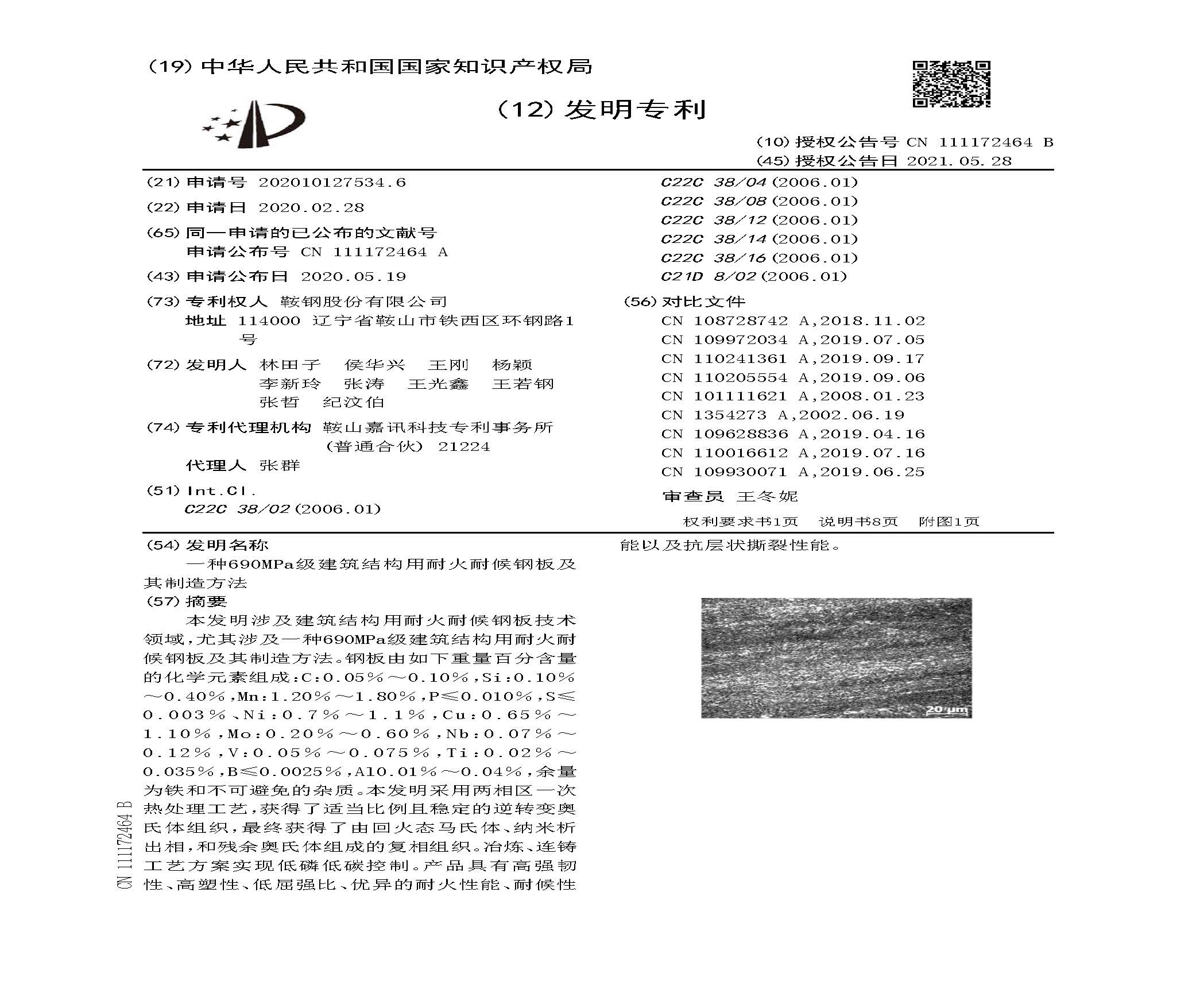

本发明涉及建筑结构用耐火耐候钢板技术领域,尤其涉及一种690MPa级建筑结构用耐火耐候钢板及其制造方法。钢板由如下重量百分含量的化学元素组成:C:0 .05%~0 .10%,Si:0 .10%~0 .40%,Mn:1 .20%~1 .80%,P≤0 .010%,S≤0 .0 0 3% 、N i :0 .7% ~1 .1% ,C u :0 .6 5% ~1 .1 0% ,M o :0 .2 0%~0 .6 0% ,N b :0 .0 7%~0 .1 2% ,V :0 .0 5%~0 .0 7 5% ,T i :0 .0 2%~0 .035%,B≤0 .0025%,Al0 .01%~0 .04%,余量为铁和不可避免的杂质。本发明采用两相区一次热处理工艺,获得了适当比例且稳定的逆转变奥氏体组织,最终获得了由回火态马氏体、纳米析出相,和残余奥氏体组成的复相组织。冶炼、连铸工艺方案实现低磷低碳控制。产品具有高强韧性、高塑性、低屈强比、优异的耐火性能、耐候性。

The invention relates to the technical field of fire-resistant and weather-resistant steel plates for building structures, in particular to a fire-resistant and weather-resistant steel plate for 690 MPa-class building structures and a manufacturing method thereof. The steel plate is composed of chemical elements with the following weight percentages: C: 0.05% to 0.10%, Si: 0.10% to 0.40%, Mn: 1.20% to 1.80%, P≤ 0.010%, S≤0.0 0 3%, Ni: 0.7% ~1.1%, C u: 0.65% ~1.10%, Mo: 0.20% ~0.60%, N b :0.07%~0.12%, V:0.05%~0.075%, Ti:0.02%~0.035% , B≤0.025%, Al0.01%~0.04%, the balance is iron and unavoidable impurities. The invention adopts the one-time heat treatment process in the two-phase zone to obtain a proper proportion and stable reverse-transformed austenite structure, and finally obtains a complex structure composed of tempered martensite, nano-precipitated phase, and retained austenite. The smelting and continuous casting process plan realizes low-phosphorus and low-carbon control. The product has high strength and toughness, high plasticity, low yield ratio, excellent fire resistance and weather resistance.