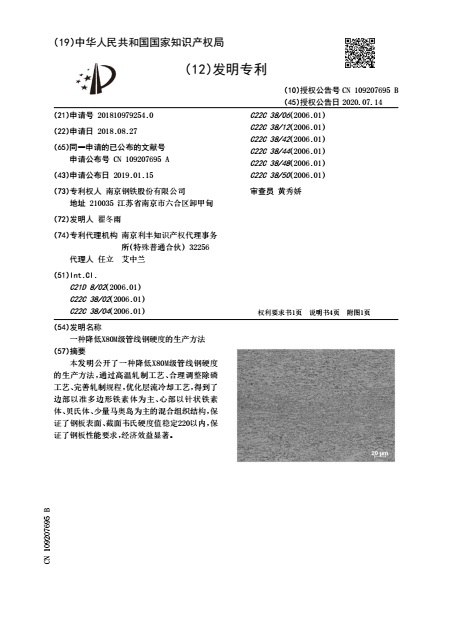

本发明公开了一种降低X80M级管线钢硬度的生产方法,通过高温轧制工艺、合理调整除磷工艺、完善轧制规程,优化层流冷却工艺,得到了边部以准多边形铁素体为主、心部以针状铁素体、贝氏体、少量马奥岛为主的混合组织结构,保证了钢板表面、截面维氏硬度值稳定220以内,保证了钢板性能要求,经济效益显著。

The invention discloses a production method for reducing the hardness of X80M grade pipeline steel, through high temperature rolling process and reasonable adjustment of phosphorus removal process, rolling schedule improvement, optimization of laminar cooling process, the edge is given priority to with quasi polygonal ferrite, heart with acicular ferrite, bainite and a small amount of the M/A island based hybrid organization structure, guarantee the stability of the steel plate surface and cross-section Vickers hardness value within 220, ensure the steel performance, economic benefit is remarkable.