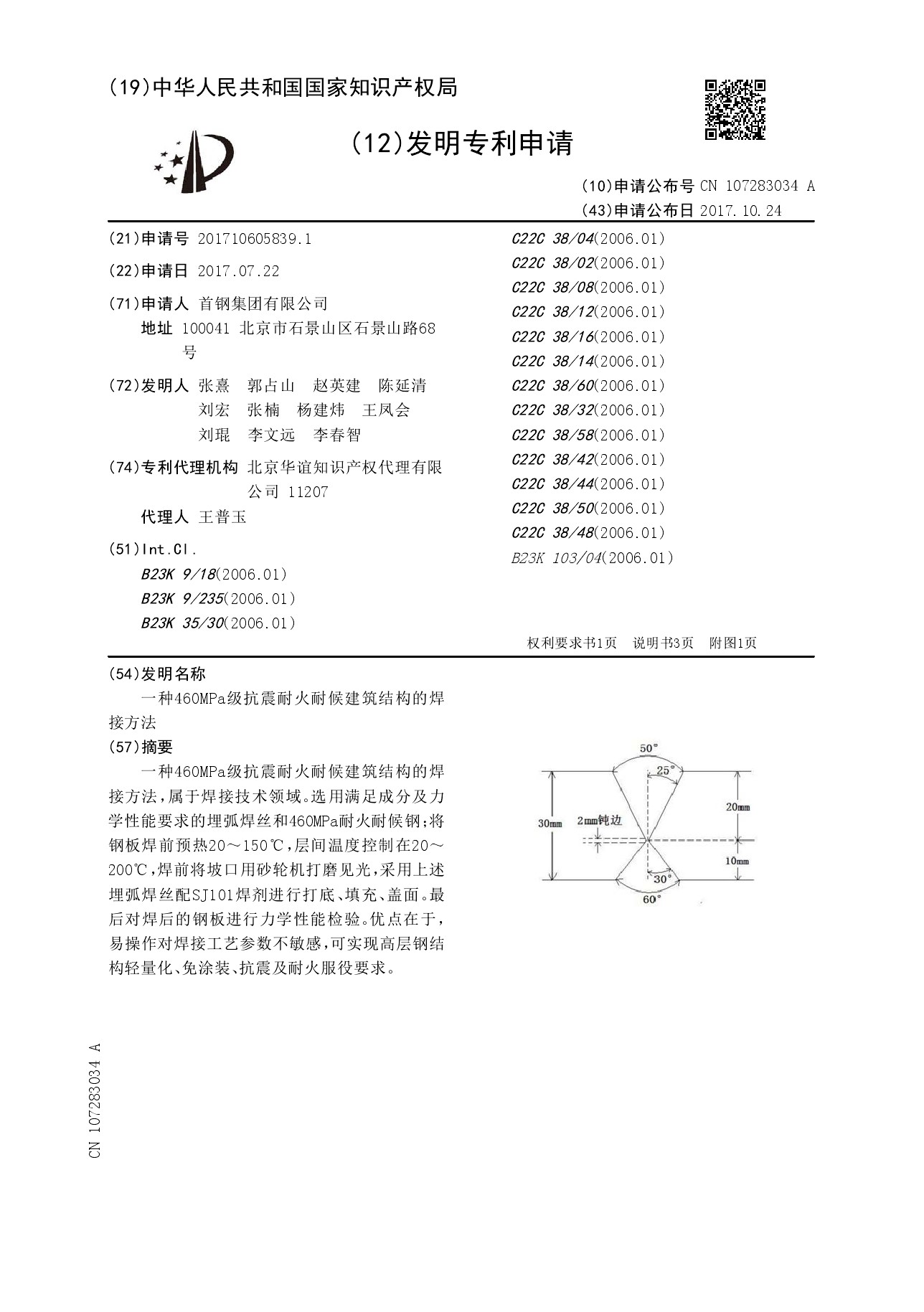

一种460MPa级抗震耐火耐候建筑结构的焊接方法,属于焊接技术领域。选用满足成分及力学性能要求的埋弧焊丝和460MPa耐火耐候钢;将钢板焊前预热20~150℃,层间温度控制在20~200℃,焊前将坡口用砂轮机打磨见光,采用上述埋弧焊丝配SJ101焊剂进行打底、填充、盖面。最后对焊后的钢板进行力学性能检验。优点在于,易操作对焊接工艺参数不敏感,可实现高层钢结构轻量化、免涂装、抗震及耐火服役要求。

The invention relates to a welding method for 460MPa seismic fire resistant and weather resistant building structures, belonging to the welding technical field. Submerged arc welding wire and 460MPa refractory steel were selected to meet the requirements of composition and mechanical properties. The steel plate is preheated at 20~150℃ before welding, and the temperature between layers is controlled at 20 ~ 200℃. The groove is polished by grinder before welding, and the submerged arc welding wire with SJ101 flux is used for bottom filling and cover. Finally, the mechanical properties of the welded steel plate are tested. The advantage is that it is easy to operate and not sensitive to welding process parameters, and it can achieve the requirements of high-rise steel structure lightweight, free of painting, seismic and fire-resistant service.