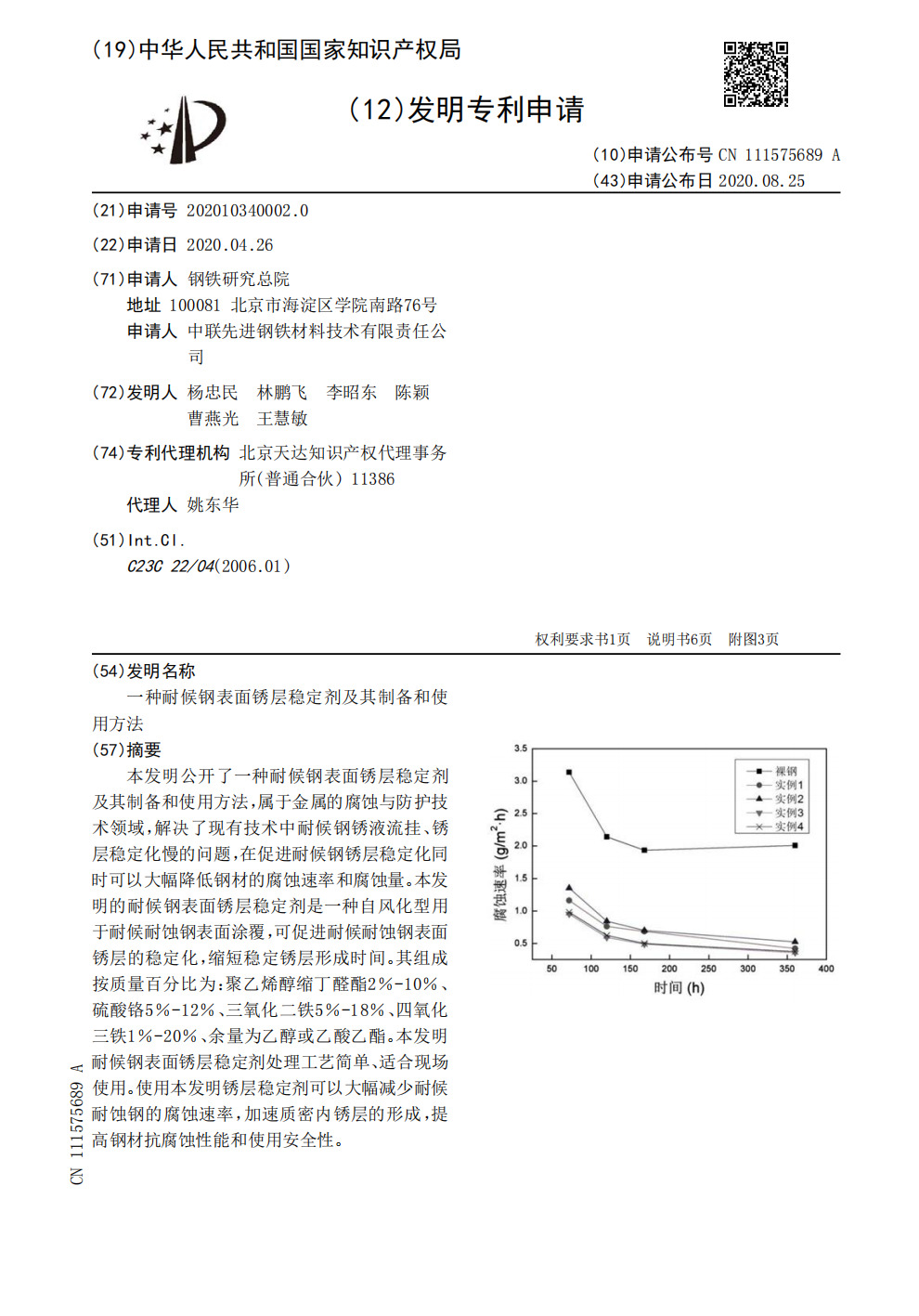

本发明公开了一种耐候钢表面锈层稳定剂及其制备和使用方法,属于金属的腐蚀与防护技术领域,解决了现有技术中耐候钢锈液流挂、锈层稳定化慢的问题,在促进耐候钢锈层稳定化同时可以大幅降低钢材的腐蚀速率和腐蚀量。本发明的耐候钢表面锈层稳定剂是一种自风化型用于耐候耐蚀钢表面涂覆,可促进耐候耐蚀钢表面锈层的稳定化,缩短稳定锈层形成时间。其组成按质量百分比为:聚乙烯醇缩丁醛酯2%-10%、硫酸铬5%-12%、三氧化二铁5%-18%、四氧化三铁1%-20%、余量为乙醇或乙酸乙酯。本发明耐候钢表面锈层稳定剂处理工艺简单、适合现场使用。使用本发明锈层稳定剂可以大幅减少耐候耐蚀钢的腐蚀速率,加速质密内锈层的形成,提高钢材抗腐蚀性能和使用安全性。

The invention discloses a rust layer stabilizer on the surface of weathering steel and its preparation and application method, which belongs to the field of metal corrosion and protection technology. It solves the problems of rust liquid hanging and slow stabilization of rust layer in existing technology. It can promote the stabilization of rust layer of weathering steel and greatly reduce the corrosion rate and corrosion amount of steel. The rust layer stabilizer for weathering steel surface is a self-weathering type used for weathering corrosion resistant steel surface coating, which can promote the stabilization of rust layer on weathering corrosion resistant steel surface and shorten the formation time of stable rust layer. The composition is as follows : polyvinyl butyral ester 2 % -10 %, chromium sulfate 5 % -12 %, ferric oxide 5 % -18 %, ferric oxide 1 % -20 %, the remainder is ethanol or ethyl acetate. The surface rust stabilizer treatment process of weathering steel is simple and suitable for field use. The use of the rust layer stabilizer in the invention can significantly reduce the corrosion rate of weather-resistant and corrosion-resistant steel, accelerate the formation of mass-density internal rust layer, and improve the corrosion resistance and safety of steel.