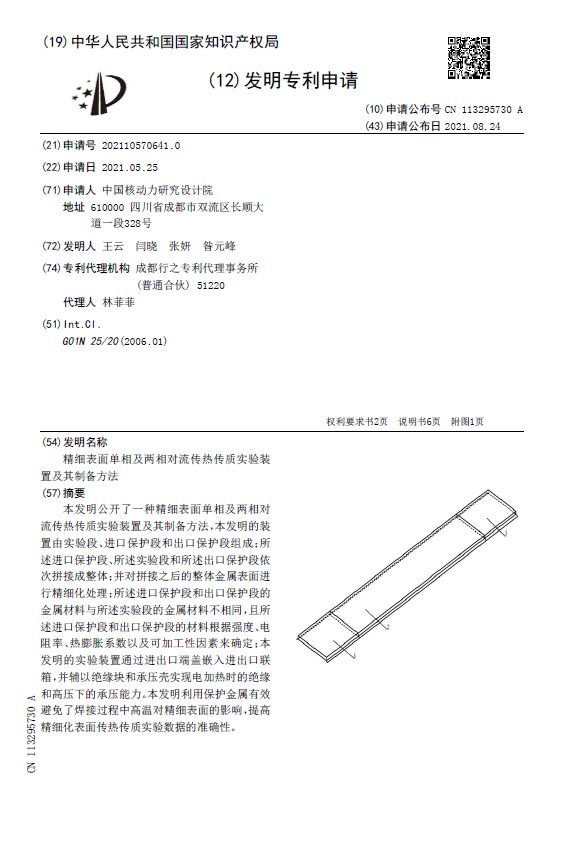

本发明公开了一种精细表面单相及两相对流传热传质实验装置及其制备方法,本发明的装置由实验段、进口保护段和出口保护段组成;所述进口保护段、所述实验段和所述出口保护段依次拼接成整体;并对拼接之后的整体金属表面进行精细化处理;所述进口保护段和出口保护段的金属材料与所述实验段的金属材料不相同,且所述进口保护段和出口保护段的材料根据强度、电阻率、热膨胀系数以及可加工性因素来确定;本发明的实验装置通过进出口端盖嵌入进出口联箱,并辅以绝缘块和承压壳实现电加热时的绝缘和高压下的承压能力。本发明利用保护金属有效避免了焊接过程中高温对精细表面的影响,提高精细化表面传热传质实验数据的准确性。

The invention discloses a single phase and two relative heat and mass transfer experimental device for fine surface and a preparation method thereof. The device comprises an experimental section, an inlet protection section and an outlet protection section; The inlet protection section, the experimental section and the outlet protection section are sequentially spliced into a whole; And the whole metal surface after stitching is refined treatment; The metal material of the inlet protection section and the outlet protection section is different from the metal material of the experimental section, and the material of the inlet protection section and the outlet protection section is determined according to the strength, resistivity, coefficient of thermal expansion and machinability factors; The experimental device of the invention is embedded into the inlet and outlet coupling box through the inlet and outlet end caps, and is assisted by an insulating block and a pressure shell to realize the insulation and bearing capacity under high pressure during electric heating. The protective metal can effectively avoid the influence of high temperature on the fine surface in the welding process and improve the accuracy of heat and mass transfer experimental data of the fine surface.