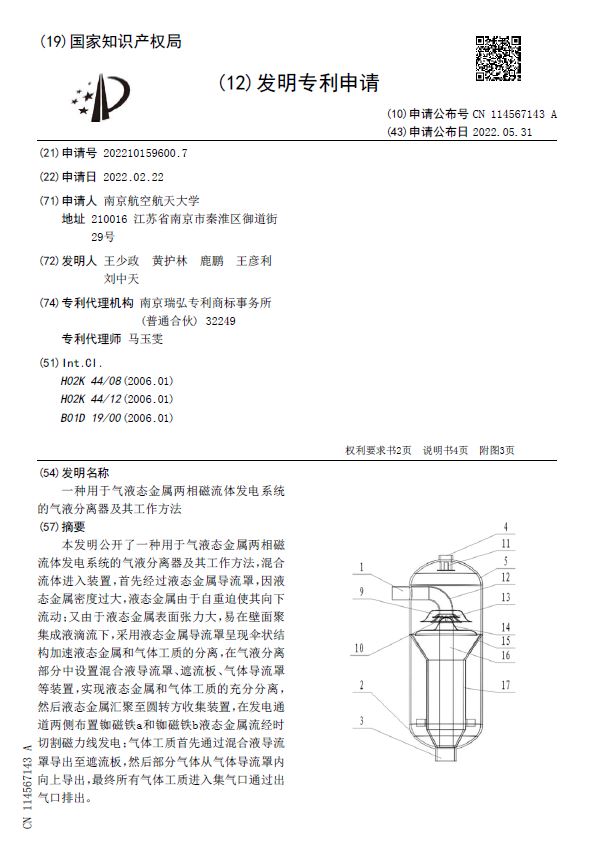

本发明公开了一种用于气液态金属两相磁流体发电系统的气液分离器及其工作方法,混合流体进入装置,首先经过液态金属导流罩,因液态金属密度过大,液态金属由于自重迫使其向下流动;又由于液态金属表面张力大,易在壁面聚集成液滴流下,采用液态金属导流罩呈现伞状结构加速液态金属和气体工质的分离,在气液分离部分中设置混合液导流罩、遮流板、气体导流罩等装置,实现液态金属和气体工质的充分分离,然后液态金属汇聚至圆转方收集装置,在发电通道两侧布置铷磁铁a和铷磁铁b液态金属流经时切割磁力线发电;气体工质首先通过混合液导流罩导出至遮流板,然后部分气体从气体导流罩内向上导出,最终所有气体工质进入集气口通过出气口排出。

The invention discloses a gas-liquid separator for a gas-liquid metal two-phase MHD power generation system and its working method. The mixed fluid enters the device and first passes through the liquid metal deflector. Because the density of the liquid metal is too large, the liquid metal is forced to flow downward due to its self-weight; Due to the high surface tension of the liquid metal, it is easy to gather into droplets on the wall surface and flow down. The liquid metal deflector is adopted to present an umbrella-like structure to accelerate the separation of liquid metal and gas working materials. The mixed liquid deflector, baffle and gas deflector are set in the gas-liquid separation part to realize the full separation of liquid metal and gas working materials. Rubidium magnet a and rubidium magnet b are arranged on both sides of the power generation channel. The gas working medium is first exported to the baffle through the mixed liquid deflector, then part of the gas is exported upward from the gas deflector, and finally all the gas working medium enters the air collecting port and is discharged through the air outlet.