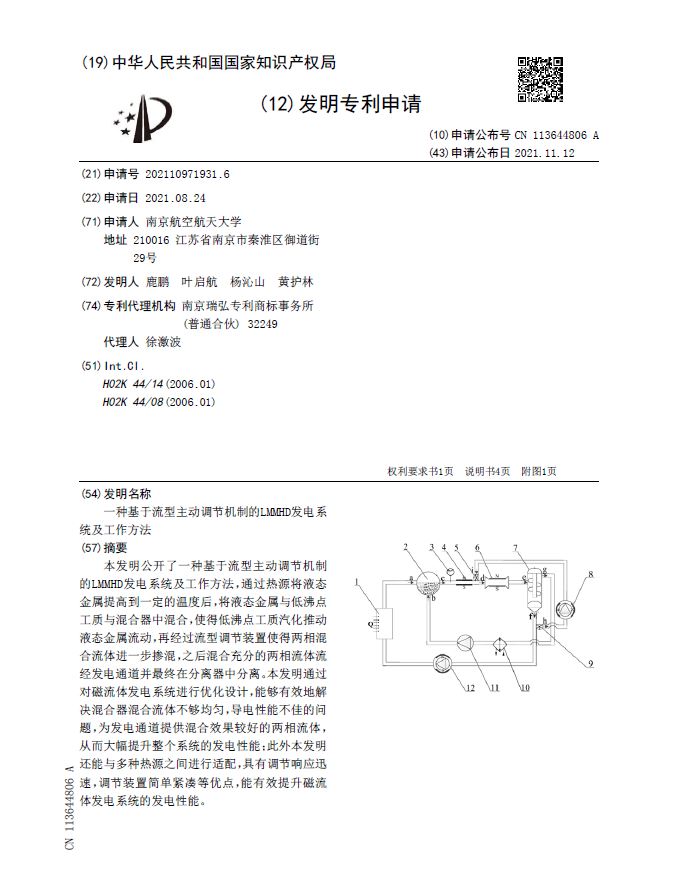

本发明公开了一种基于流型主动调节机制的LMMHD发电系统及工作方法,通过热源将液态金属提高到一定的温度后,将液态金属与低沸点工质与混合器中混合,使得低沸点工质汽化推动液态金属流动,再经过流型调节装置使得两相混合流体进一步掺混,之后混合充分的两相流体流经发电通道并最终在分离器中分离。本发明通过对磁流体发电系统进行优化设计,能够有效地解决混合器混合流体不够均匀,导电性能不佳的问题,为发电通道提供混合效果较好的两相流体,从而大幅提升整个系统的发电性能;此外本发明还能与多种热源之间进行适配,具有调节响应迅速,调节装置简单紧凑等优点,能有效提升磁流体发电系统的发电性能。

The invention discloses a LMMHD power generation system and working method based on the flow pattern active regulation mechanism. After the liquid metal is raised to a certain temperature by the heat source, the liquid metal and the low boiling point working medium are mixed with the mixer, so that the low boiling point working medium is vaporized to promote the liquid metal flow, and then the two phases of the mixed fluid are further mixed through the flow pattern regulation device. The fully mixed two-phase fluid then flows through the power channel and is eventually separated in a separator. By optimizing the design of the MHD power generation system, the invention can effectively solve the problem that the mixing fluid of the mixer is not uniform and the conductivity is poor, and provide the two-phase fluid with good mixing effect for the power generation channel, thus greatly improving the power generation performance of the whole system. In addition, the invention can be adapted to a variety of heat sources, has the advantages of rapid adjustment response, simple and compact adjustment device, etc., and can effectively improve the power generation performance of the MHD power generation system.