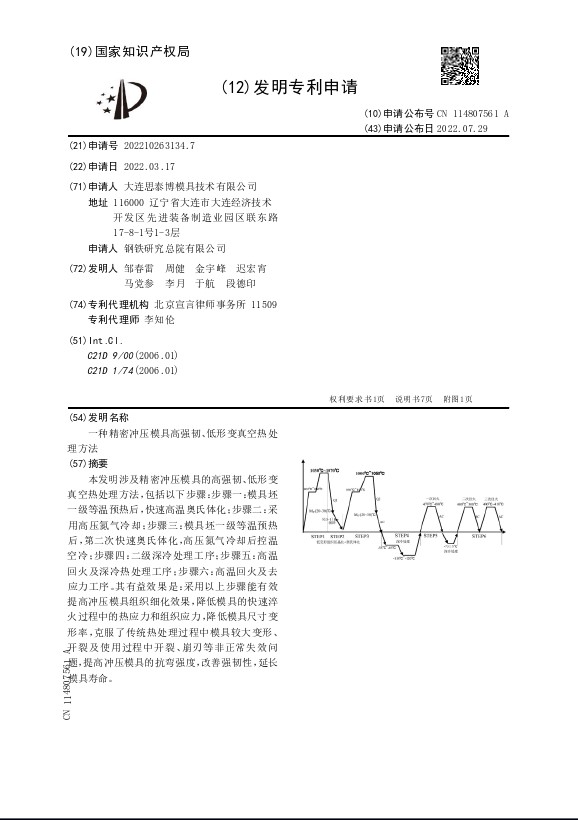

本发明涉及精密冲压模具的高强韧、低形变真空热处理方法,包括以下步骤:步骤一:模具坯一级等温预热后,快速高温奥氏体化;步骤二:采用高压氮气冷却;步骤三:模具坯一级等温预热后,第二次快速奥氏体化,高压氮气冷却后控温空冷;步骤四:二级深冷处理工序;步骤五:高温回火及深冷热处理工序;步骤六:高温回火及去应力工序。其有益效果是:采用以上步骤能有效提高冲压模具组织细化效果,降低模具的快速淬火过程中的热应力和组织应力,降低模具尺寸变形率,克服了传统热处理过程中模具较大变形、开裂及使用过程中开裂、崩刃等非正常失效问题,提高冲压模具的抗弯强度,改善强韧性,延长模具寿命。

The invention relates to a vacuum heat treatment method with high strength, toughness and low deformation for precision stamping dies, which comprises the following steps: step 1: rapid high temperature austenitizing of die blank after one-stage isothermal preheating; Step 2: use high-pressure nitrogen for cooling; Step 3: after the first isothermal preheating of the mold blank, the second rapid austenitizing, the high pressure nitrogen cooling and the temperature control air cooling; Step 4: secondary cryogenic treatment process; Step 5: high temperature tempering and deep cold heat treatment process; Step 6: high-temperature tempering and stress relief process. Its beneficial effect is that the above steps can effectively improve the effect of refining the structure of the stamping die, reduce the thermal stress and structural stress in the rapid quenching process of the die, reduce the deformation rate of the die size, overcome the large deformation and cracking of the die in the traditional heat treatment process and the abnormal failure problems such as cracking and chipping during use, improve the bending strength of the stamping die, improve the strength and toughness, and extend the life of the die.