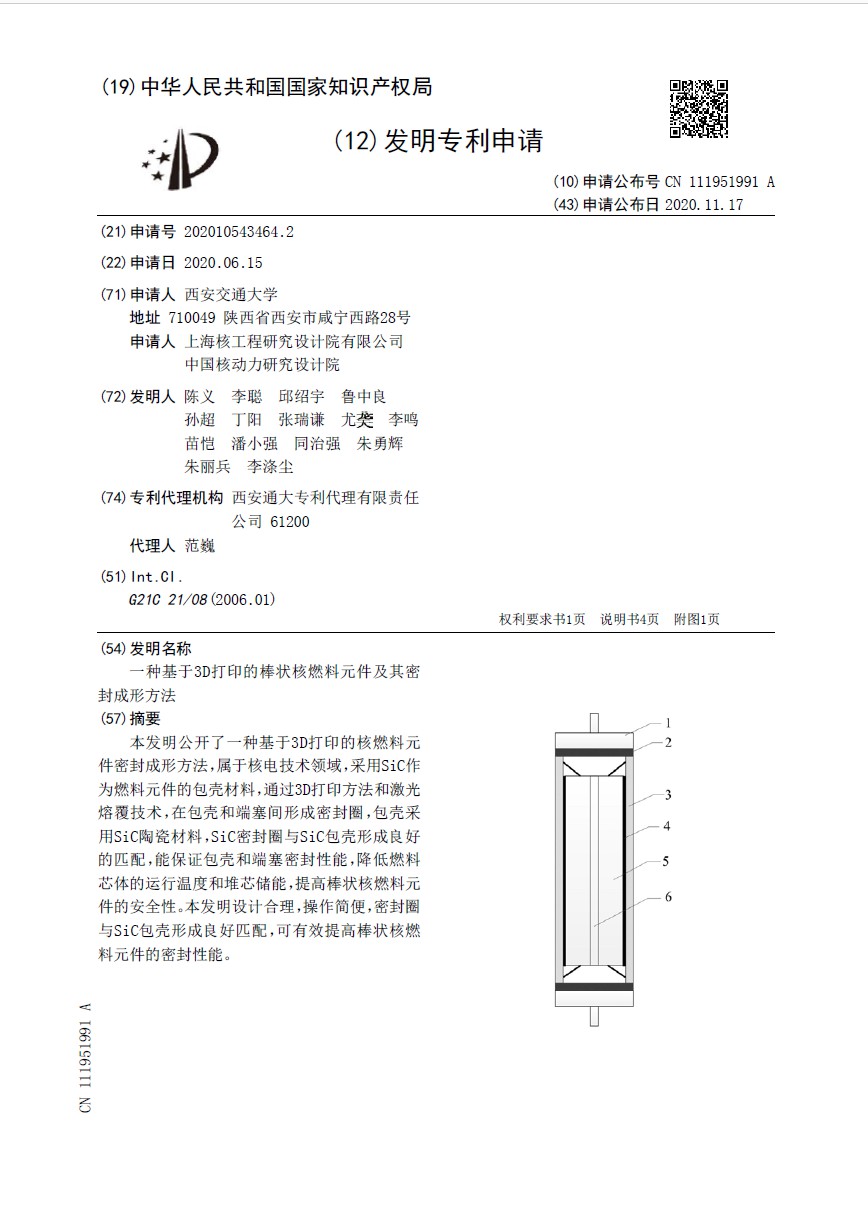

本发明公开了一种基于3D打印的核燃料元件密封成形方法,属于核电技术领域,采用SiC作为燃料元件的包壳材料,通过3D打印方法和激光熔覆技术,在包壳和端塞间形成密封圈,包壳采用SiC陶瓷材料,SiC密封圈与SiC包壳形成良好的匹配,能保证包壳和端塞密封性能,降低燃料芯体的运行温度和堆芯储能,提高棒状核燃料元件的安全性。本发明设计合理,操作简便,密封圈与SiC包壳形成良好匹配,可有效提高棒状核燃料元件的密封性能。

The invention discloses a nuclear fuel element sealing forming method based on 3D printing, which belongs to the technical field of nuclear power. The invention has reasonable design and simple and convenient operation, the sealing ring and the SiC cladding form good matching, and the sealing performance of the rod-shaped nuclear fuel element can be effectively improved.