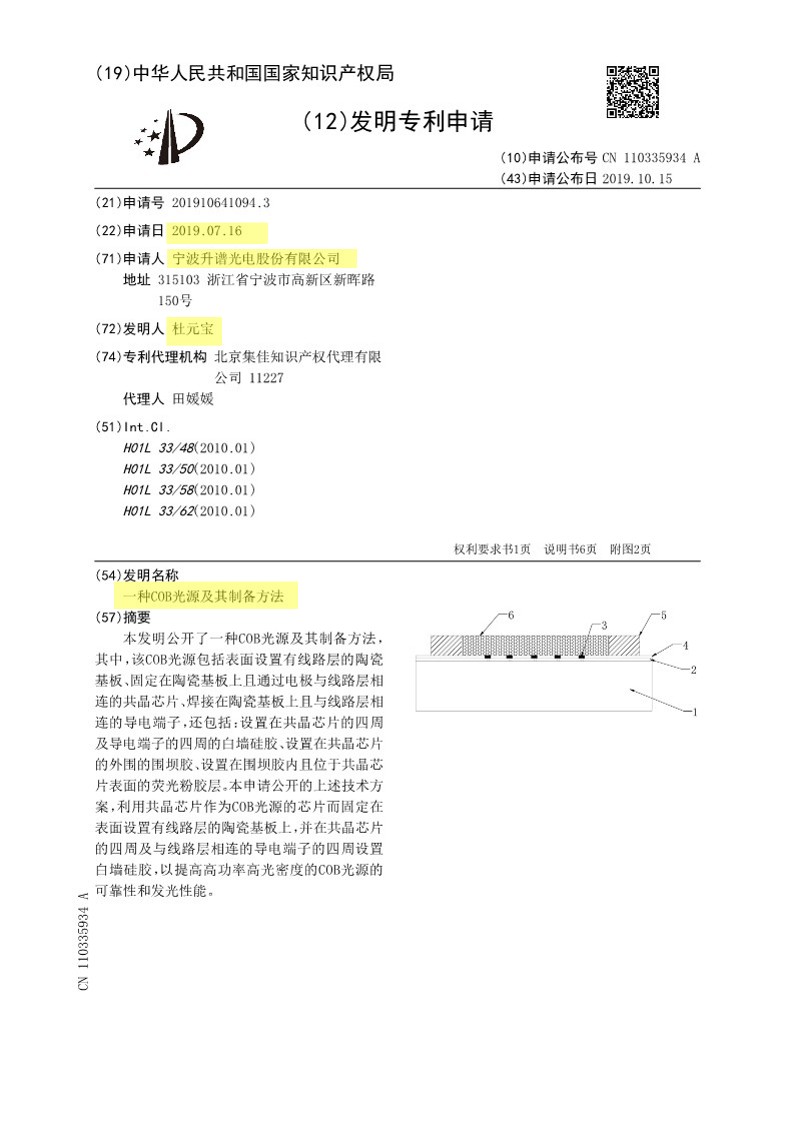

本发明公开了一种COB光源及其制备方法,其中,该COB光源包括表面设置有线路层的陶瓷基板、固定在陶瓷基板上且通过电极与线路层相连的共晶芯片、焊接在陶瓷基板上且与线路层相连的导电端子,还包括:设置在共晶芯片的四周及导电端子的四周的白墙硅胶、设置在共晶芯片的外围的围坝胶、设置在围坝胶内且位于共晶芯片表面的荧光粉胶层。本申请公开的上述技术方案,利用共晶芯片作为COB光源的芯片而固定在表面设置有线路层的陶瓷基板上,并在共晶芯片的四周及与线路层相连的导电端子的四周设置白墙硅胶,以提高高功率高光密度的COB光源的可靠性和发光性能。

The invention discloses a COB light source and a preparation method thereof, wherein the COB light source comprises a ceramic substrate provided with a circuit layer on the surface, a eutectic chip fixed on the ceramic substrate and connected with the circuit layer through an electrode, a conductive terminal welded on the ceramic substrate and connected with the circuit layer, and also includes: The white wall silica gel is arranged around the eutectic chip and around the conductive terminal, the dam glue is arranged on the periphery of the eutectic chip, and the phosphor glue layer is arranged in the dam glue and located on the surface of the eutectic chip. This application and open the above technical scheme, the use of eutectic die as the COB light chip circuitry and fixed on the surface layer of ceramic substrate, and around the perimeter of the eutectic die and around the perimeter of the conductive terminals are connected to the circuit layer set white silica gel, in order to improve the high power high density of COB reliability and lighting performance.