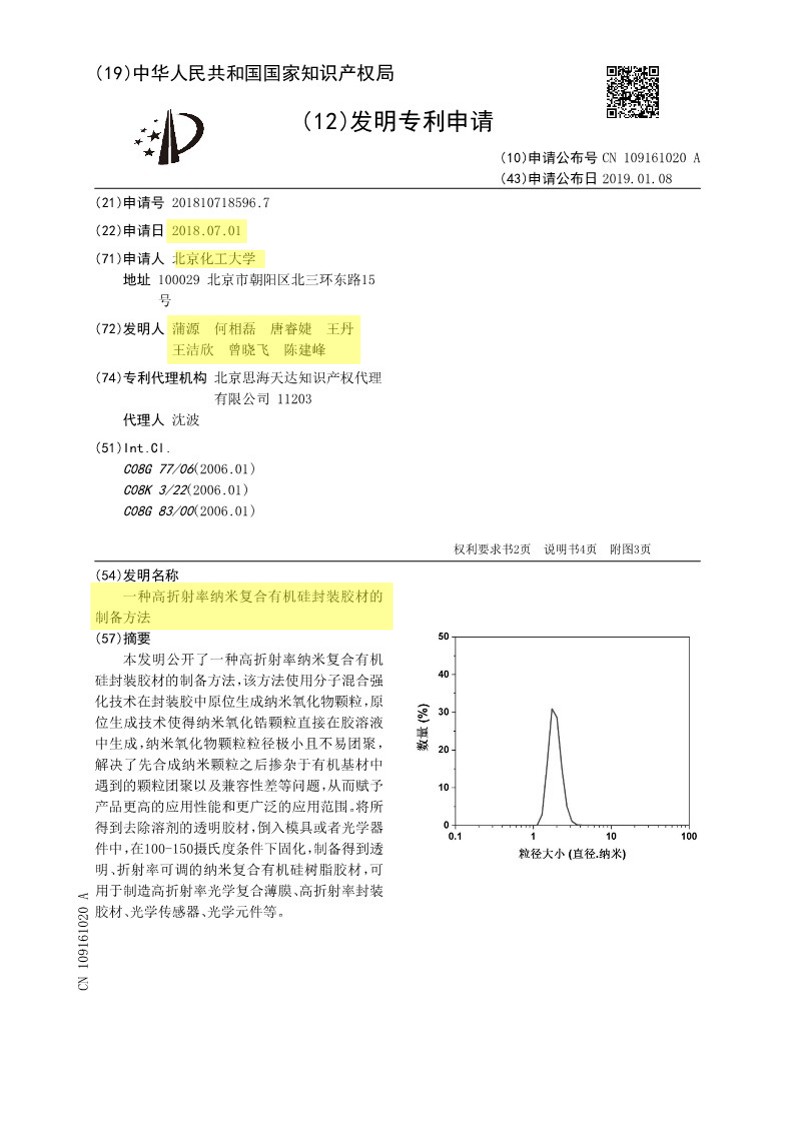

本发明公开了一种高折射率纳米复合有机硅封装胶材的制备方法,该方法使用分子混合强化技术在封装胶中原位生成纳米氧化物颗粒,原位生成技术使得纳米氧化锆颗粒直接在胶溶液中生成,纳米氧化物颗粒粒径极小且不易团聚,解决了先合成纳米颗粒之后掺杂于有机基材中遇到的颗粒团聚以及兼容性差等问题,从而赋予产品更高的应用性能和更广泛的应用范围。将所得到去除溶剂的透明胶材,倒入模具或者光学器件中,在100-150摄氏度条件下固化,制备得到透明、折射率可调的纳米复合有机硅树脂胶材,可用于制造高折射率光学复合薄膜、高折射率封装胶材、光学传感器、光学元件等。

The invention discloses a kind of high refractive index nano composite organic silicon encapsulating materials preparation methods, the method USES molecular hybrid reinforcement technology in encapsulation adhesive in situ generated oxide nanoparticles, in situ generation technique makes the nano zirconia particles generated in the colloidal solution directly, nano oxide particle size small and not easy to reunite, It solves the problems of particle agglomeration and poor compatibility when the nanoparticles are first synthesized and then doped into the organic substrate so as to give the product higher application performance and wider application range. The obtained transparent adhesive material with solvent removal is poured into molds or optical devices and cured at 100-150 degrees Celsius to prepare transparent nano-composite silicone resin material with adjustable refractive index, which can be used to manufacture high refractive index optical composite film, high refractive index encapsulation adhesive material, optical sensors, optical components, etc.