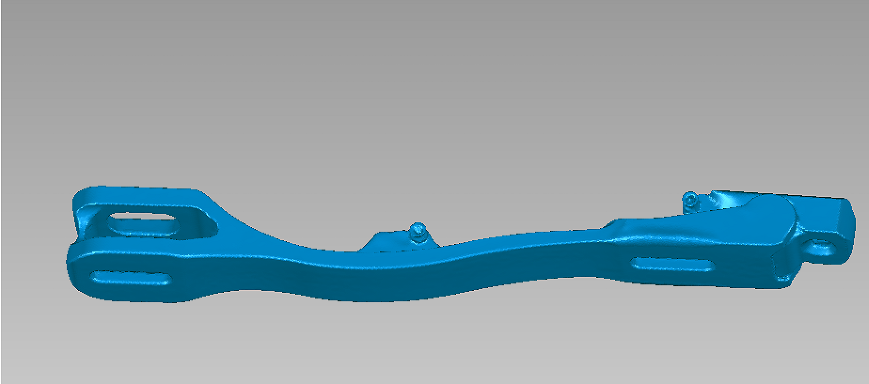

速滑鞋刀托几何模型需要利用三维激光扫描仪(加拿大,creaform handyscan700)扫描速滑鞋刀托,扫描分辨率为 0.8mm ,将刀托放在贴好标记点的旋转台上,扫描正面和反面,后期通过合并获得刀托的点云数据,保存数据类型为 STL 格式。将三维激光扫描采集的速滑鞋STL 格式文件导入 GEOMAGIC DESIGN X软件中,通过点云过滤杂点、点云采样、点云平滑等步骤对点云模型进行处理。然后利用领域组划分功能,通过识别原始扫描数据的 3D 特征,自动分类特征领域,将敏感度设置为 10,面片粗糙程度设置为中间位置。根据速滑鞋坐标系通过“手动对齐”命令创建坐标系。模型构建主要包括创建轮廓、创建片体、创建倒圆角等步骤,最终得到刀托的实体模型。最后将建好的速滑鞋实体模型输出 STEP 格式文件。

The geometric model of the speed skate knife holder needs to be scanned with a 3D laser scanner (Canada, createform handyscan 700) with a scanning resolution of 0.8mm. The knife holder is placed on the rotary table with the marked points, and the front and back sides are scanned. Later, the point cloud data of the knife holder is obtained by merging, and the data type is STL format. Import the STL format file of speed skating shoes collected by 3D laser scanning into GEOMAGIC DESIGN X software, and process the point cloud model through point cloud filtering, point cloud sampling, point cloud smoothing and other steps. Then use the domain group division function to automatically classify the feature fields by identifying the 3D features of the original scanning data, set the sensitivity to 10, and set the patch roughness to the middle position. Create a coordinate system based on the speed skate coordinate system through the "Manual Alignment" command. The model construction mainly includes the steps of creating the profile, creating the slice, creating the fillet, and finally obtaining the solid model of the tool holder. Finally, the built solid model of speed skating shoes will be exported to STEP format file.