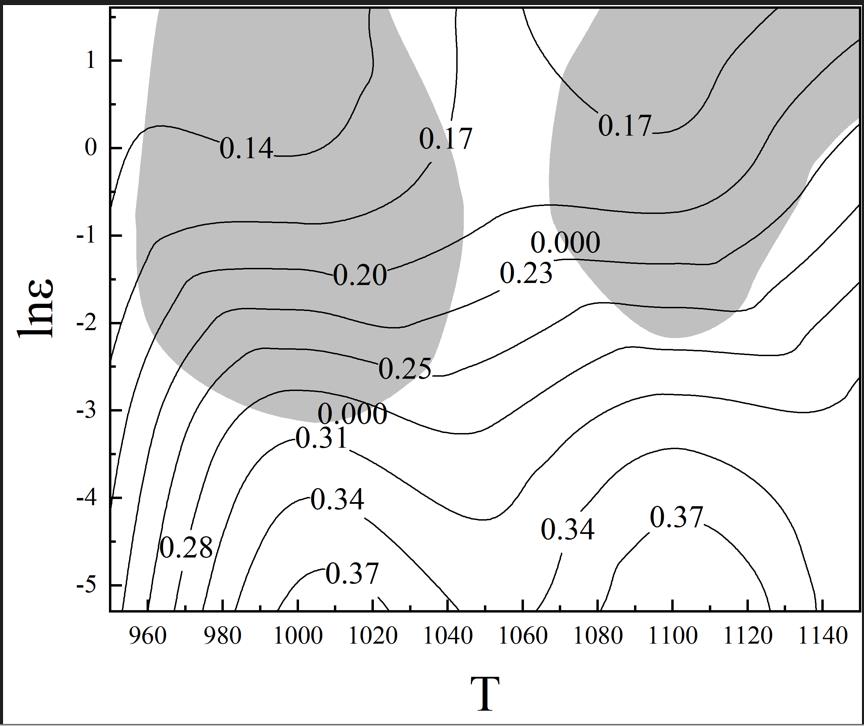

对刀背材料进行热模拟压缩实验。采用Gleeble进行热变形模拟的试样尺寸为Φ8 mm*12 mm,将试样以5 ℃·s-1速度加热至变形温度并保温5 min后开始压缩变形,变形结束后水冷。压缩试验所采用的温度分别为950、1000、1050、1100和1150 ℃,相应的应变速率为0.005、0.05、0.5和5s-1。将压缩后试样沿直径纵向切开制成金相试样,试样表面经过180# - 5000#砂纸打磨后继续使用1.5 μm的金刚石抛光剂对其进行抛光,使用腐蚀液(10HNO3+90C2H5OH)进行擦拭腐蚀。利用SEM观察其显微组织。使用Origin软件对数据进行分析绘制出热加工图。

The thermal simulation compression experiment is carried out for the knife back material. The sample size of Gleeble for thermal deformation simulation is Φ 8 mm * 12 mm, heat the sample to the deformation temperature at the speed of 5 ℃ · s-1 and keep it for 5 min before compression deformation, and water cooling after deformation. The temperatures used in the compression test are 950, 1000, 1050, 1100 and 1150 ℃ respectively, and the corresponding strain rates are 0.005, 0.05, 0.5 and 5s-1. Cut the compressed sample longitudinally along the diameter to make a metallographic sample, and continue to use 1.5 after the sample surface is polished with 180 # - 5000 # abrasive paper μ M of diamond polishing agent to polish it, and use corrosion liquid (10HNO3+90C2H5OH) to wipe and corrode it. The microstructure was observed by SEM. Use Origin software to analyze the data and draw the thermal processing diagram.