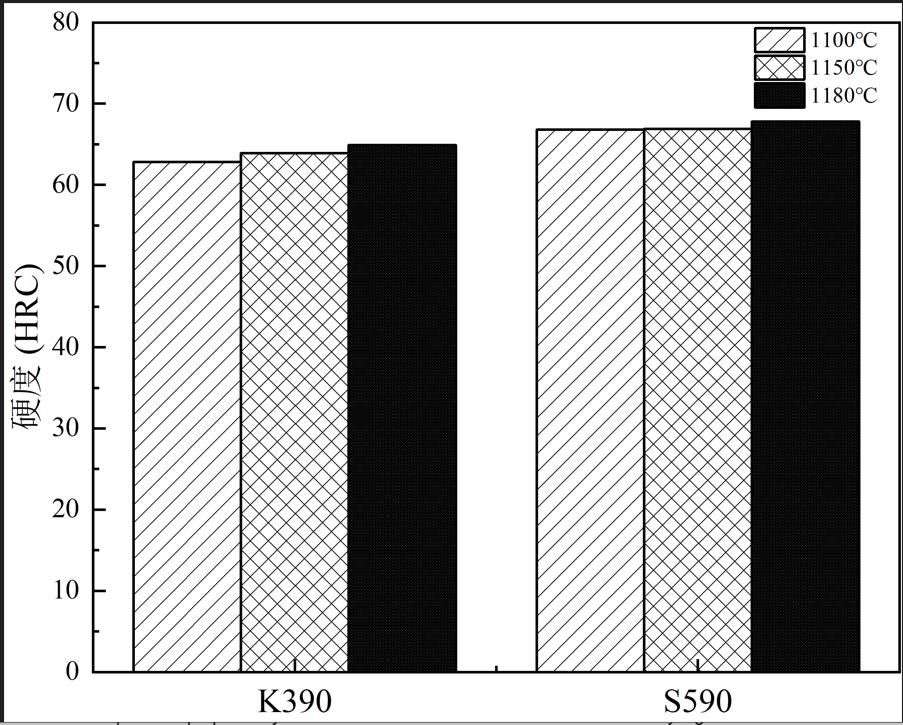

K390和S590刀刃均选择三个淬火温度1100 ℃,1150 ℃,1180 ℃,相同的回火工艺(深冷和550 ℃回火三次),对热处理过程中以及热处理后的样品进行显微硬度(HV)测试,两种钢的硬度随着淬火温度的上升而上升,淬火温度为1180 ℃时,K390的硬度达到64.9,S590的硬度达到67.8。

Three quenching temperatures of 1100 ℃, 1150 ℃ and 1180 ℃ are selected for K390 and S590 blades. The same tempering process (cryogenic and 550 ℃ tempering for three times) is used to test the microhardness (HV) of the samples during and after heat treatment. The hardness of the two steels increases with the increase of quenching temperature. When the quenching temperature is 1180 ℃, the hardness of K390 reaches 64.9 and the hardness of S590 reaches 67.8.