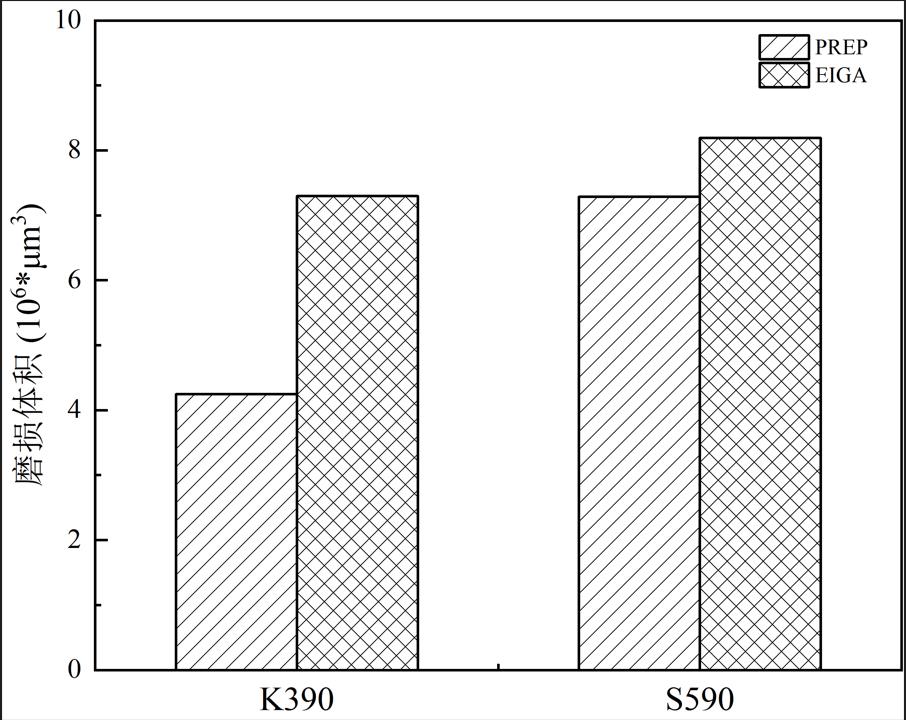

将均采用PREP和EIGA两种制粉方法制备的K390和S590粉末制成合金锭后,经过1150 ℃热处理后取样进行摩擦磨损试验,两种材料均是在PREP方法下磨损体积更低,耐磨性更好,分别为3.366*106 μm3和6.007*106 μm3,相比于EIGA方法,耐磨性能提高了68%、19.8%。

K390 and S590 powders prepared by both PREP and EIGA methods are made into alloy ingots. After heat treatment at 1150 ℃, samples are taken for friction and wear tests. Both materials have lower wear volume and better wear resistance under the PREP method, 3.366 * 106 respectively μ M3 and 6.007 * 106 μ M3, compared with EIGA method, the wear resistance is increased by 68% and 19.8%.