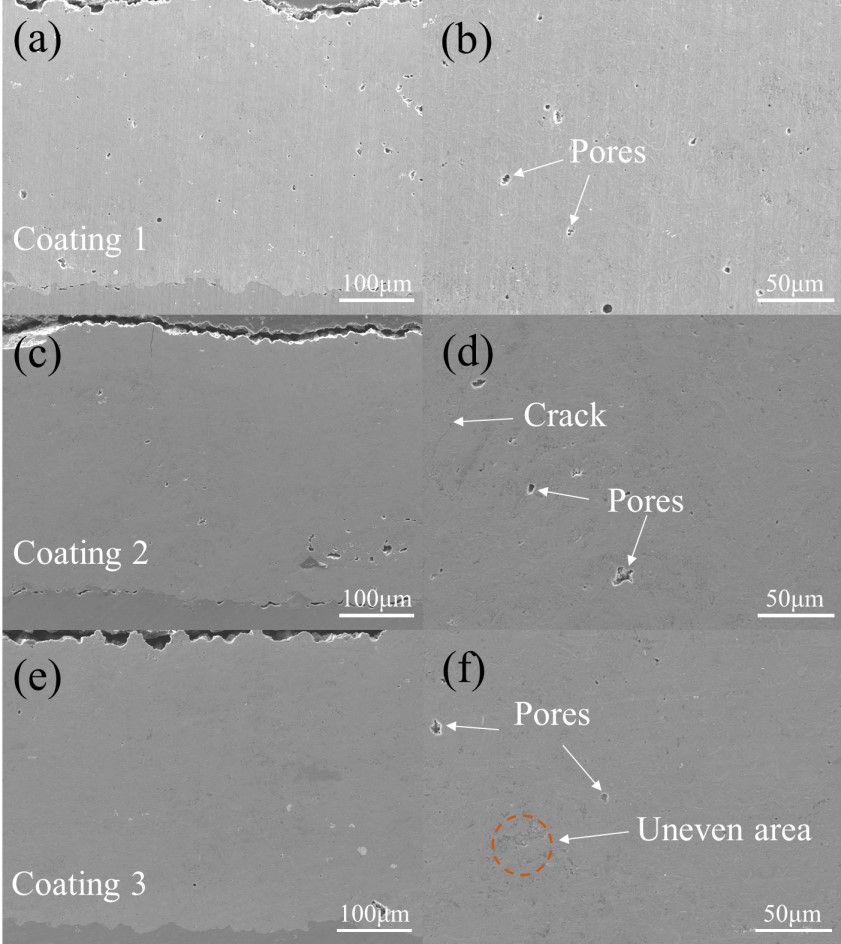

图为三种涂层横截面照片。可以看出,涂层的厚度均在350~400 μm,与基体结合紧密,在结合处没有明显的缝隙。使用灰度法测得涂层孔隙率分别约为0.44%、0.33%和0.39%,除了涂层存在少量裂纹和喷涂不均匀的区域,三种涂层结合较为致密。这是由于较快的喷涂速度使颗粒以扁平化的形态与基体接触,增大了接触面积,使熔融的颗粒散热速率加快,减小了晶粒形核生长的机率,提高了涂层的致密性。

Figure shows the cross-sectional photographs of the three coatings. It can be seen that the thicknesses of the coatings are all in the range of 350-400 μm, and they are tightly bonded to the substrate with no obvious gaps at the bond. The porosity of the coatings measured using the grayscale method was about 0.44%, 0.33% and 0.39%, respectively. Except for a small amount of cracks and unevenly sprayed areas of the coatings, the three coatings were more densely bonded. This is because the faster spraying speed makes the particles contact with the substrate in a flattened form, which increases the contact area and accelerates the heat dissipation rate of the molten particles, reducing the chance of grain nucleation growth and improving the denseness of the coating.