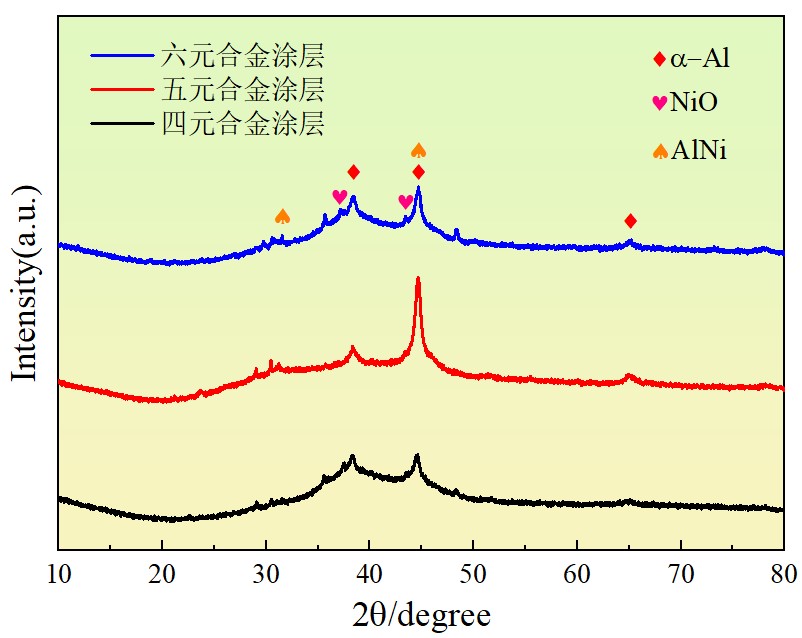

采用课题一研制的四元、五元、六元非晶合金粉末,使用课题三研制的低温高速火焰喷涂再制造成套技术装备制备非晶纳米晶合金涂层。图为非晶纳米晶合金涂层的XRD图谱。从图中可知,三种涂层在2θ=34°~48°均存在一个明显的漫散射峰,这是典型的非晶特征,说明涂层主要是非晶态的,同时涂层中产生了晶化物和氧化相。经计算,四元、五元和六元合金涂层非晶含量分别约为85%、96%和90%。涂层的高非晶含量是由于低温高速火焰喷涂过程中以氮气代替氧气作为载入气体,提供的冷却速度高于非晶形成的临界冷却速率,以及降低了涂层的氧化物和晶化相的含量。

The amorphous nanocrystalline alloy coating is prepared by using the quadruple, quintuple and hexametallic amorphous alloy powder developed by subject one and the low-temperature high-speed flame spraying remanufacturing set of technology and equipment developed by subject three. Figure shows the XRD patterns of the amorphous nanocrystalline alloy coatings. From the figure, it can be seen that there is an obvious diffuse scattering peak at 2θ=34°~48° for all three coatings, which is a typical amorphous feature, indicating that the coatings are mainly amorphous, while the crystalline and oxide phases are produced in the coatings. The amorphous content of the coatings was calculated to be about 85%, 96% and 90% for the tetradentate, pentadentate and hexadentate alloys, respectively. The high amorphous content of the coatings is due to the replacement of oxygen with nitrogen as the loading gas during the low-temperature, high-speed flame spraying process, which provides a cooling rate higher than the critical cooling rate for amorphous formation, as well as reduces the content of oxide and crystalline phases in the coatings.