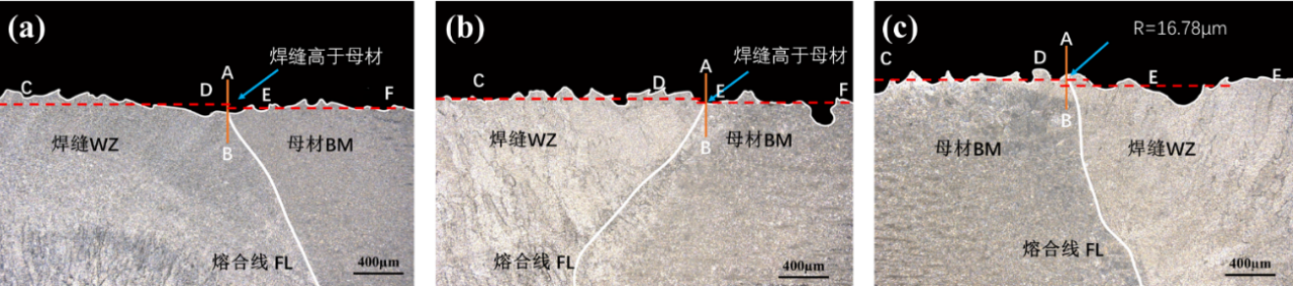

金属焊接-图9-钢筋焊接接头在达叻现场腐蚀2年后的腐蚀台阶(a)400E,(b)CE-1,(a)CE-2 (焊接方法:熔化极气体保护焊,焊接电流250A, 焊接电压29V,焊接速度300min/min, 焊接线能量14.5kJ/cm)

可以看出三种钢筋焊接接头的焊缝均高于或等于母材,说明设计的焊材耐蚀性优于母材,适用于钢筋焊接接头的使用。

Metal welding - Figure 9 - corrosion steps of steel welded joints after 2 years of corrosion in Dalat site (a) 400e, (b) CE-1, (a) CE-2 (welding method: GMAW, welding current 250A, welding voltage 29V, welding speed 300min / min, welding line energy 14.5kj/cm)

It can be seen that the welding seam of three kinds of steel welded joints is higher than or equal to the base metal, which indicates that the corrosion resistance of the designed welding material is better than that of the base metal, and it is suitable for the use of steel welded joints.