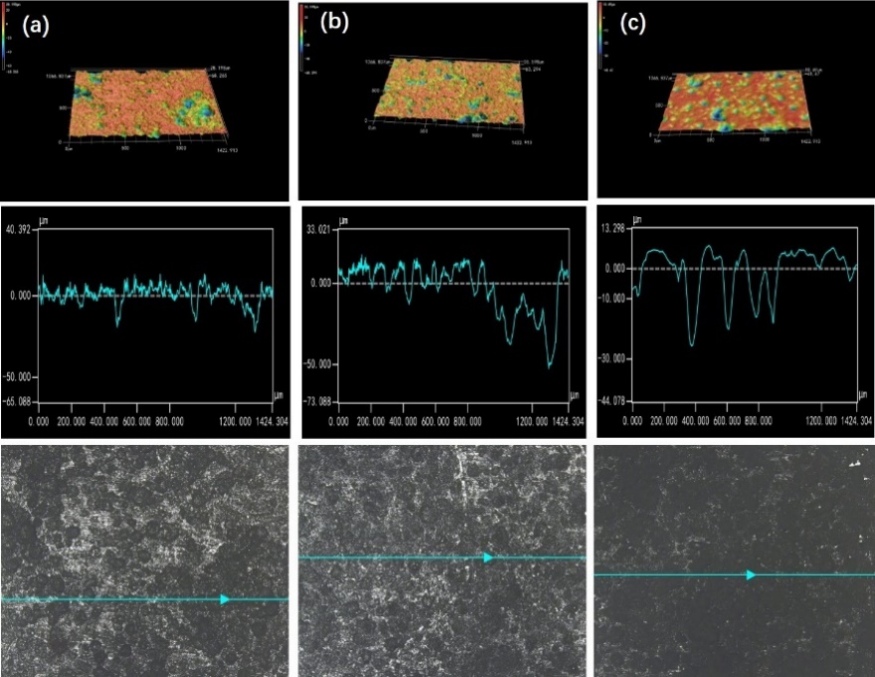

金属焊接-图8-420实芯焊接接头在达叻现场腐蚀1年后的表面轮廓(a)母材,(b)热影响区,(c)焊缝。焊接参数(埋弧焊,焊接电流550A,焊接电压30V,焊接速度450mm/min, 焊接线能量 22kJ/cm)

对于1年试样,焊接接头母材、熔合线和焊缝区均受到不同程度的腐蚀,表面布满了大大小小的点蚀坑。从点蚀坑的直径和深度来看,母材区腐蚀轻微,而热影响区和焊缝区腐蚀较为严重,说明热影响区与焊缝区是腐蚀薄弱的位置。对于2年试样,不同区域的腐蚀形貌不同,整体呈均匀腐蚀状态,相较于1年试样腐蚀更为严重。

Metal welding - Fig. 7-420 the macro morphology and corrosion steps of solid core welding sample after pickling in Thailand Dalat. Welding parameters (submerged arc welding, welding current 550A, welding voltage 30V, welding speed 450mm / min, welding line energy 22kj / cm)

For one year sample, the base metal, fusion line and weld area of welding joint are corroded to different degrees, and the surface is covered with pitting pits. From the diameter and depth of pitting pit, the corrosion in base metal area is slight, while the corrosion in heat affected area and weld area is serious, which indicates that the weak corrosion position is between the heat affected area and the weld area. For 2-year samples, the corrosion morphology of different regions is different, and the overall corrosion is uniform, which is more serious than that of the samples in 1 year.