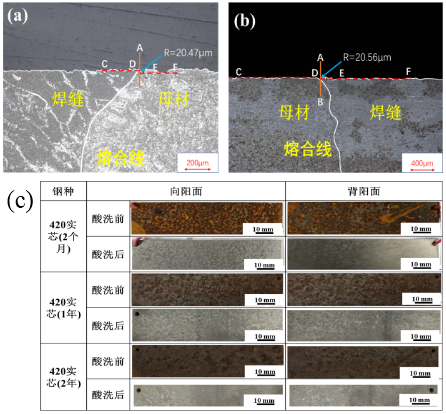

金属焊接-图7-420实芯焊接样泰国达叻暴晒取回酸洗后宏观形貌及腐蚀台阶。焊接参数(埋弧焊,焊接电流550A,焊接电压30V,焊接速度450mm/min, 焊接线能量 22kJ/cm)

其中,2个月锈层试样基体上分布有红褐色的腐蚀产物斑点,斑点均匀分布于整个基体试样上,向阳面和背阳面相差不大。1年锈层试样基体上分布有灰色的腐蚀产物,腐蚀产物颜色较浅,腐蚀产物斑点均匀分布于基体上。2年锈层试样颜色加深,腐蚀产物分布更为致密,说明锈层的保护性增强。去除腐蚀产物后焊接接头表面颜色呈浅色,并随着腐蚀周期的增加,焊缝区比母材区颜色加深,说明焊接接头表面存在腐蚀不均匀特点,且随腐蚀周期增加逐渐明显,但整体腐蚀形貌颜色差异不大。 1年后的试样焊缝区与母材区存在腐蚀台阶,母材区比焊缝区腐蚀较轻一些,焊缝区台阶高度较低,R=20.47μm,但是R值小于30μm,说明焊接接头试样合格。2年后的试样同样存在腐蚀台阶,焊缝区台阶高度较低,R=20.56μm,但是R值小于30μm,说明焊接接头试样合格。

Metal welding - Fig. 7-420 the macro morphology and corrosion steps of solid core welding sample after pickling in Thailand Dalat. Welding parameters (submerged arc welding, welding current 550A, welding voltage 30V, welding speed 450mm / min, welding line energy 22kj / cm)

Among them, there are reddish brown corrosion product spots distributed on the substrate of 2-month rust layer sample, and the spots are evenly distributed on the whole substrate sample, with little difference between the sunny surface and the back sunny surface. Gray corrosion products were distributed on the substrate of 1-year rust layer samples, and the color of corrosion products was lighter, and the corrosion product spots were evenly distributed on the substrate. The results show that the color of rust layer is deeper and the distribution of corrosion products is more compact, which indicates that the protection of rust layer is enhanced. After removing the corrosion products, the color of the welded joint surface is light, and with the increase of corrosion cycle, the color of the weld area is deeper than that of the base metal area, which indicates that there is uneven corrosion on the welded joint surface, and it is gradually obvious with the increase of corrosion cycle, but the color difference of the overall corrosion morphology is not large. One year later, there are corrosion steps between the weld zone and the base metal zone, the corrosion of the base metal zone is lighter than that of the weld zone, and the step height of the weld zone is lower, r = 20.47 μ m. But r is less than 30 μ m. It indicates that the welded joint sample is qualified. After 2 years, there are also corrosion steps in the sample, and the step height in the weld area is lower, r = 20.56 μ m. But r is less than 30 μ m. It indicates that the welded joint sample is qualified.