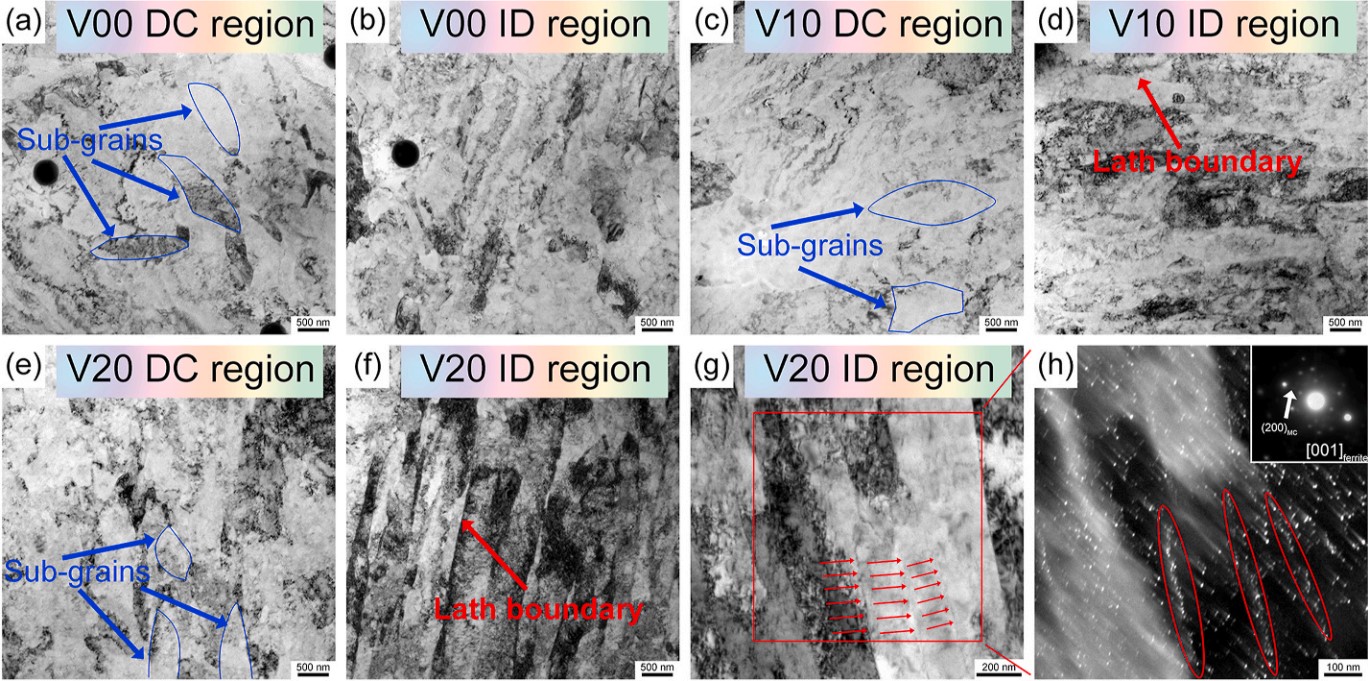

所有样品枝晶干区域没有清楚地观察到板条边界,因为这些板条边界是焊后热处理过程中位错湮灭的主要场所。此外,如图(a)、(c)和(e)中的蓝色箭头所示,在枝晶干区域观察到通过位错湮灭的分裂板条产生的一些亚晶粒。对于枝晶间区域,随着焊后热处理试样中 V 含量的增加,板条边界逐渐变得更加明显,这表明纳米级 M2C 碳化物对板条边界的钉扎作用弱于纳米级 MC 碳化物。板条边界相当数量的纳米级 MC 碳化物可以在焊后热处理过程中对边界运动提供强大的阻力,如图(g)-(h)中的红色矩形区域所示。 V20焊后热处理试样中枝晶间 区域的钉扎效应似乎比 V10焊后热处理试样中的强,因为由于更多溶解的 V 原子和更高的位错密度,板条边界上可能存在更高密度的纳米级 MC 碳化物。此外,V20焊后热处理试样中枝晶间区域更多的板条内纳米级 MC 碳化物可能作为位错运动的障碍,这是阻止子边界形成的原因。因此,ID 区域的位错密度在 V20焊后热处理试样中最高,如图 (f)所示。

All lath boundaries were not clearly detected at DC region because these lath boundaries were the primary sites for the annihilation of dislocations during PWHT process. Furthermore, some sub-grains resulting from the divided laths through the annihilation of dislocations were observed at DC region, as indicated by blue arrows in Fig (a), (c) and (e) . For ID region, the lath boundaries gradually became more pronounced with the increase of the V contents in PWHT specimens, which indicated that the pinning effect of the nano-scale M2C carbides on lath boundaries was weaker than that of the nano-scale MC carbides. A considerable number of nano-scale MC carbides decorating the lath boundaries could provide strong resistance to the boundaries motion during PWHT process, as shown in the red rectangular area in Fig (g)–(h). The pinning effect appeared to be stronger at ID region in V20 PWHT specimen than that in V10 PWHT specimen because a higher density of nano-scale MC carbides was probably present on the lath boundaries as a result of more dissolved V atoms and higher dislocation densities. Furthermore, the more intra-lath nano-scale MC carbides at ID region in V20 PWHT specimen may act as obstacles for dislocations motion, which was responsible for preventing the formation of sub-boundaries. Thus, the dislocation density at ID region was the highest in the V20 PWHT specimen, as shown in Fig (f).