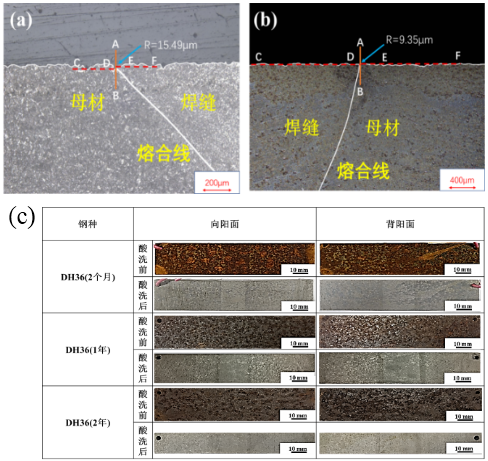

金属焊接-图1-DH36焊接样泰国达叻暴晒取回酸洗后宏观形貌及腐蚀台阶。通过CO2气体保护焊(250A, 29V, 300mm/min, 14.5 kJ/cm)。

从图中可以看出,2个月锈层试样基体上分布有红褐色的腐蚀产物斑点,斑点均匀分布于整个基体试样上。1年锈层试样基体上分布有灰色的腐蚀产物,腐蚀产物颜色较浅,腐蚀产物斑点均匀分布于基体上。2年锈层试样基体上分布灰黑色腐蚀产物,相比于前两个周期,腐蚀产物更致密。去除腐蚀产物后三种焊接接头的焊缝区与母材区有明显的界限,说明焊缝区与母材区腐蚀存在一定的差别,并且腐蚀形貌差异随着周期增加更为明显。 试样焊缝区与母材区存在一定的腐蚀台阶,母材区比焊缝区腐蚀较轻一些,焊缝区台阶高度较低。1年的R=15.49μm,2年的R=9.35μm,这一现象与样品及测量误差有关,但是R值都小于30μm,说明DH36焊接接头试样合格。

Metal welding - Fig. 1-DH36 welding joint was exposed to the sun, and the macro morphology and corrosion steps after pickling were taken back. Through CO2 gas shielded welding (250A, 29V, 300mm / min, 14.5 kJ / cm).

It can be seen from the figure that there are reddish brown corrosion product spots distributed on the matrix of 2-month rust layer sample, and the spots are evenly distributed on the whole matrix sample. Gray corrosion products were distributed on the substrate of 1-year rust layer samples, and the color of corrosion products was lighter, and the corrosion product spots were evenly distributed on the substrate. Gray black corrosion products were distributed on the substrate of 2-year rust layer samples, and the corrosion products were denser than those in the first two cycles. After removing the corrosion products, there is an obvious boundary between the weld zone and the base metal zone, which indicates that there is a certain difference in corrosion between the weld zone and the base metal zone, and the difference in corrosion morphology is more obvious with the increase of the cycle. There are some corrosion steps between the weld zone and the base metal zone. The corrosion of the base metal zone is lighter than that of the weld zone, and the step height of the weld zone is lower. 1 year R = 15.49 μ m. 2 years R = 9.35 μ m. This phenomenon is related to the sample and measurement error, but the R value is less than 30 μ m. It indicates that DH36 welded joint sample is qualified.