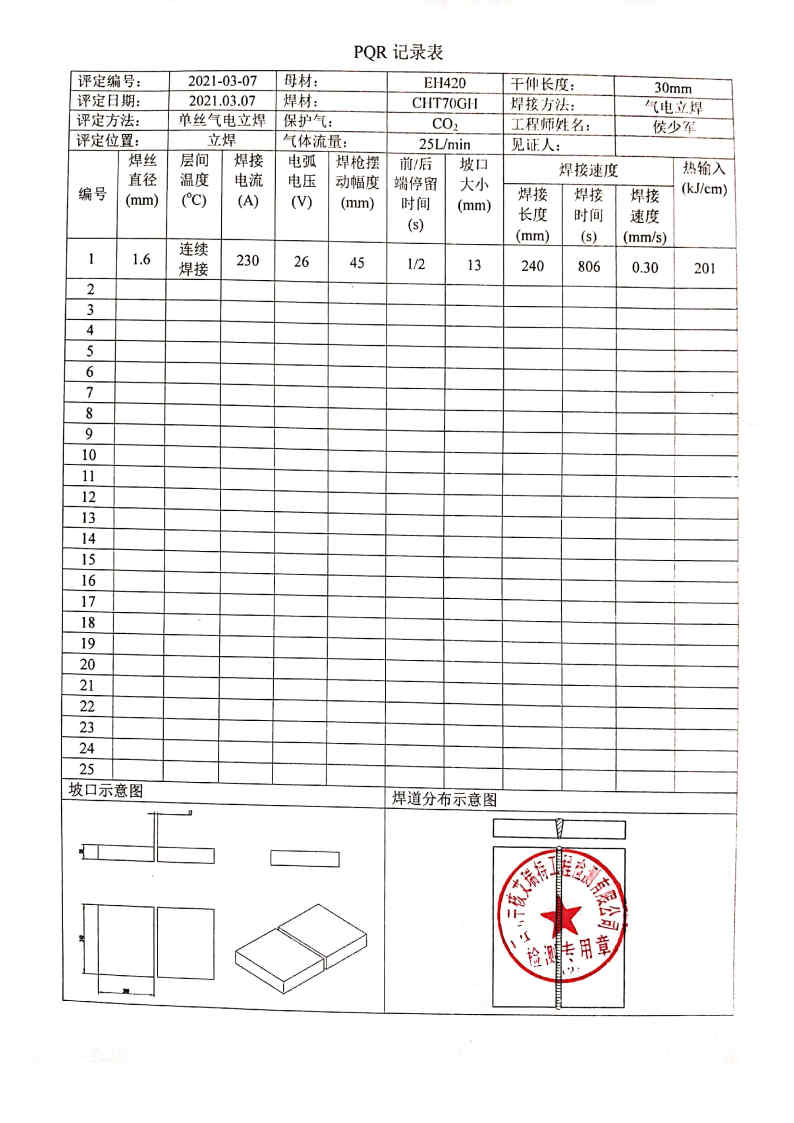

设计了适合海工钢厚板窄间隙大线能量焊接的专用焊枪,并在此基础上开发大线能量窄间隙焊接技术:包括焊接平台搭建、焊炬设计优化、自动焊接控制系统建立。针对系列规格厚度的海洋工程用钢,开发与板材对应的规定热量输入条件下的窄间隙焊接工艺和方法,在此基础上对接头可靠性进行评估,具体包括接头拉伸性能、焊缝区、熔合线区以及热影响区的低温冲击性能。对不同热输入下系列规格海工钢焊接接头性能进行分析。其中,线能量为201 kJ/cm的EH420接头屈服强度大于420 MPa,抗拉强度大于552 MPa,接头断裂在热影响区处。焊缝区的-40°C冲击功超过57 J,熔合线处的-40°C冲击功超过150 J,弯曲试样表面无裂纹。线能量为151 kJ/cm的EH460厚板接头屈服强度大于460 MPa,抗拉强度大于690 MPa,接头断裂在热影响区处。焊缝区-40°C冲击功超过88 J,熔合线处的-40°C冲击功超过81 J。线能量为105 kJ/cm的EH500厚板接头屈服强度大于500 MPa,抗拉强度超过625 MPa,接头断裂在母材处。焊缝区-40°C冲击功大于80 J,熔合线处的-40°C冲击功超过126 J,弯曲试样表面无裂纹。最后,对EH550厚板进行了50 kJ/cm线能量窄间隙MAG焊试验,获得了成形均匀良好的焊缝。焊缝区以针状铁素体为主,生长方向由熔合线指向焊缝中心,同时含有晶界铁素体,焊缝层内位置的针状铁素体比层间位置的针状铁素体尺寸更大。热影响区的组织包括针状铁素体与晶界铁素体,并含有少量块状铁素体。焊接接头屈服强度大于550 MPa,抗拉强度超过700 MPa,拉伸试样断裂在母材处。焊缝区的-40°C冲击功超过112 J,熔合线处的-40°C冲击功超过276 J。

A special welding torch suitable for heavy plate narrow gap welding of Marine engineering steel was designed, and the technology of narrow gap welding of heavy wire energy was developed. The properties of welded joints with different heat inputs were analyzed. The yield strength and tensile strength of EH420 joint with line energy of 201 kJ/cm were greater than 420 MPa and 552 MPa respectively, and the joint was fractured in the heat-affected zone. The impact energy at -40 °C in the weld zone and fusion line exceeded 57 J and 150 J respectively. The yield strength and tensile strength of EH460 thick-plate joint with line energy of 151 kJ/cm were greater than 460 MPa and 690 MPa respectively, and the joint was also fractured in the heat-affected zone. The impact energy at -40 °C in the weld zone and fusion line exceeded 88 J and 81 J respectively. The yield strength and tensile strength of EH500 thick-plate joint with line energy of 105 kJ/cm were more than 500 MPa and 625 MPa respectively. The joint was fractured at the base metal. The impact energy at -40 °C in the weld zone was greater than 80 J, and the impact energy at -40°C at the fusion line was greater than 126 J. No cracks existed on the joint of the bent samples. Finally, narrow gap MAG welding process with 50 kJ/cm line energy was used to welding EH550 thick-plate. Uniform and well-formed joint was obtained. The yield strength of the joint was greater than 550 MPa and the tensile strength was more than 700 MPa. The impact energy at -40°C in the weld zone exceeded 112 J, and the impact energy at -40°C at the fusion line exceeded 276 J.