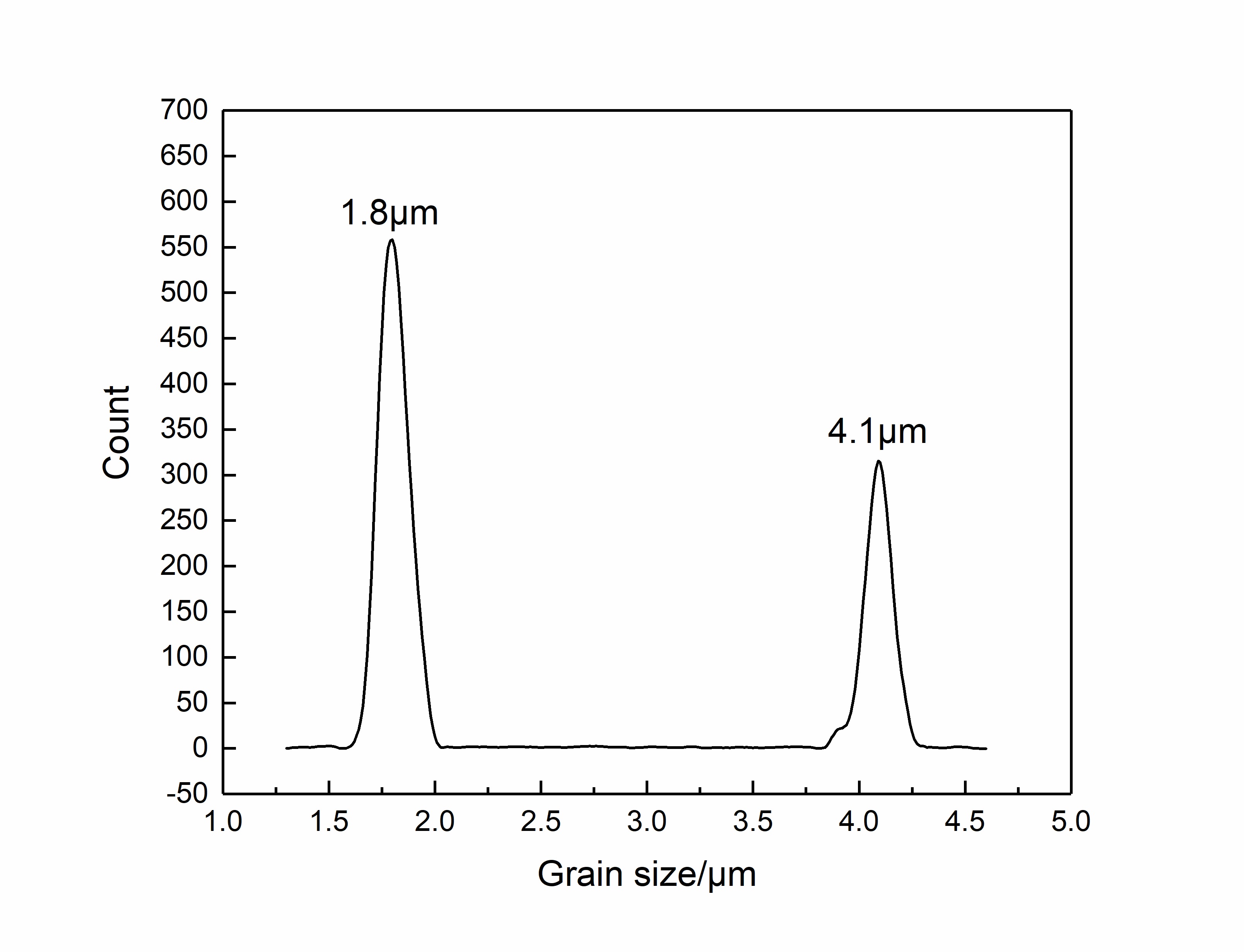

将超细粉末烧结体热轧件打磨抛光,采用2.3g NaOH+2.6g K3[Fe (CN)6]+20ml蒸馏水混合制备的金相腐蚀液并对抛光后的试样进行腐蚀,腐蚀时间为90s,随后在Mx6Rt型金相显微镜下观测其金相组织。得到金相组织图后,使用图像处理软件调整图片对比度,然后用Image Pro Plus软件拟合标距后,采用图像法对晶粒尺寸进行统计分析,得出其晶粒度。

The hot-rolled part of the ultrafine powder sintered body is polished, and the metallographic etching solution prepared by mixing 2.3g NaOH+2.6g K3[Fe (CN)6]+20ml distilled water is used to corrode the polished sample. The corrosion time is 90s, and then observe its metallographic structure under the Mx6Rt type metallographic microscope. After obtaining the metallographic structure map, use image processing software to adjust the contrast of the picture, and then use Image Pro Plus software to fit the gauge length, and use the image method to statistically analyze the grain size to obtain its grain size.