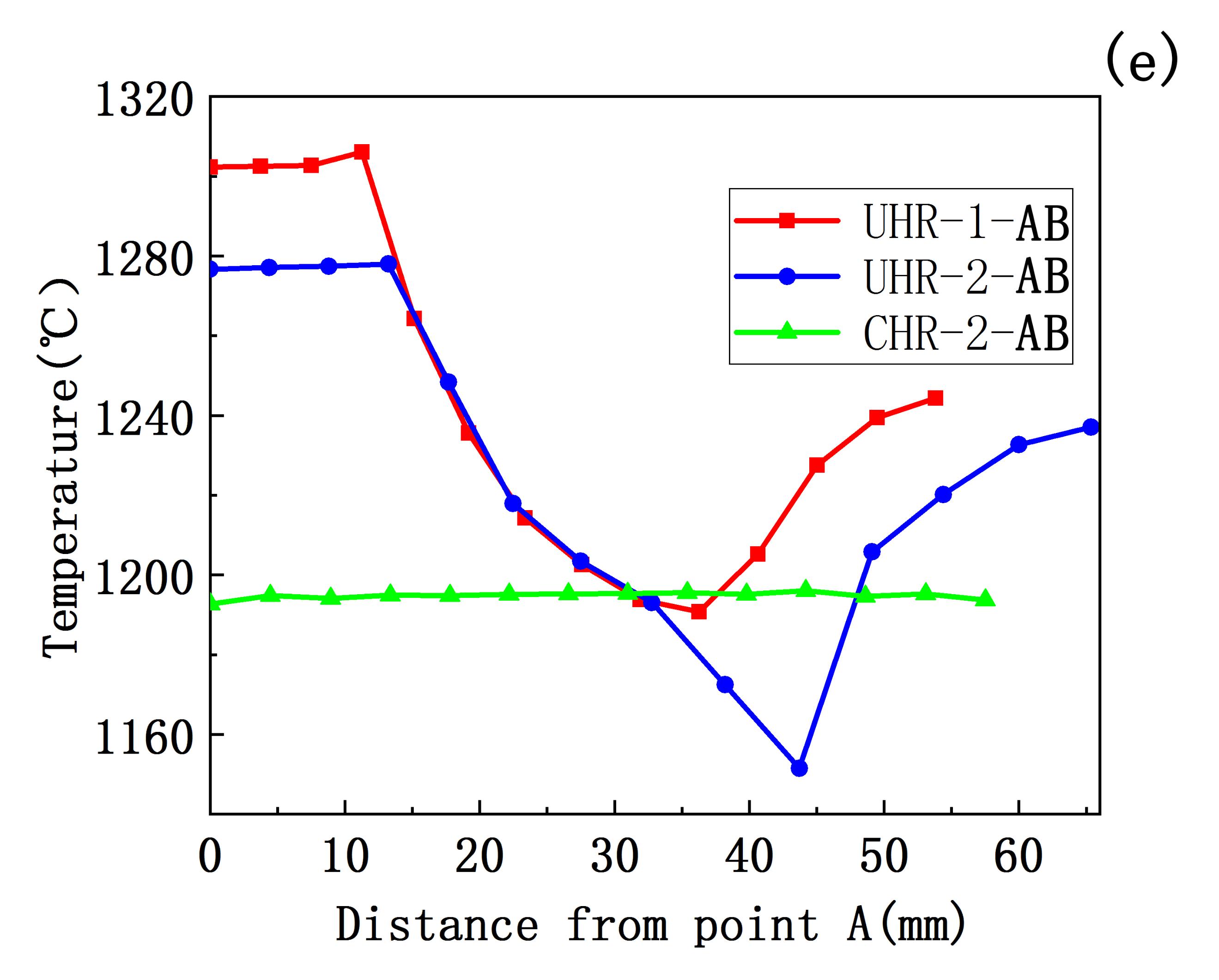

根据以上本构回归开发了纯钼应变补偿形式的数值模型材料库,并通过大型通用有限元仿真平台MSC.Marc 2014对纯钼常见的单向热轧(UHR)与交叉热轧(CHR)两种工艺进行模拟对比,分析其轧制变形区场量(温度场、应力场、应变场)差异化,并用附加应力/应变场量解释等效场量形成客观原因。红外高温计测量板表面温度以提高模型温度场精度。最后着重研究不同加工参数对表面激冷层深度的影响。

Based on the above constitutive regression, a numerical model material library in the form of strain compensation for pure molybdenum has been developed, and the two common unidirectional hot rolling (UHR) and cross hot rolling (CHR) The two processes are simulated and compared to analyze the difference of the rolling deformation area (temperature field, stress field, strain field), and use the additional stress/strain field to explain the objective reason for the formation of the equivalent field. The infrared pyrometer measures the surface temperature of the board to improve the accuracy of the model temperature field. Finally, it focuses on the influence of different processing parameters on the depth of the surface chilled layer.