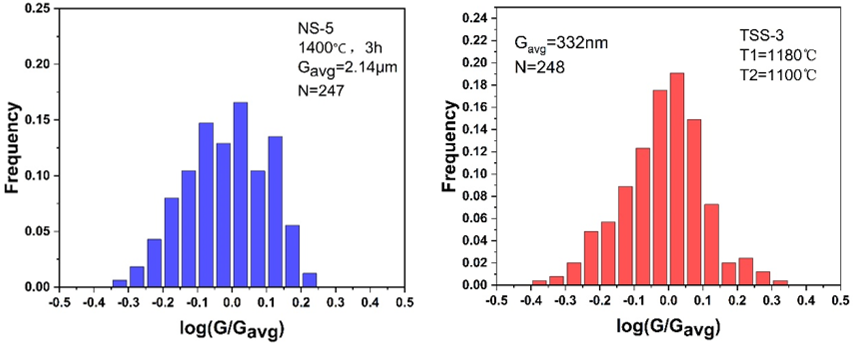

首先采用溶液燃烧法和纯氢还原法制备Mo纳米粉末,以钨酸铵(NH4)6H2W12O40为前驱体。粉末在单轴力下进行压制。烧结实验在高纯氢气气氛中进行,采用了两种不同的加热方案:(i)恒定加热速率烧结,即在不保温的情况下,以5 ℃/min的速度将坯体加热至预设温度(900-1500℃),然后以10 ℃/min的速度冷却至室温。这些实验用于研究烧结动力学,并寻找合适的第一步烧结条件以优化两步烧结;(ii)两步烧结,将生坯加热至T1,然后冷却至T2并长时间保温。采用阿基米德法测得烧结样品的密度。样品的断口在FEI Quanta FEG 450场发射扫描电镜下进行观测,并通过SEM图片测量晶粒的平均晶粒尺寸。

First, the solution combustion method and pure hydrogen reduction method are used to prepare Mo nano-powder, with ammonium tungstate (NH4)6H2W12O40 as the precursor. The powder is compressed under uniaxial force. The sintering experiment was carried out in a high-purity hydrogen atmosphere, and two different heating schemes were used: (i) Constant heating rate sintering, that is, the green body is heated to the preset temperature at a rate of 5 ℃/min without holding the temperature. (900-1500℃), then cool to room temperature at a rate of 10 ℃/min. These experiments are used to study the sintering kinetics and find suitable first-step sintering conditions to optimize the two-step sintering; (ii) Two-step sintering, heating the green body to T1, then cooling to T2 and keeping it for a long time. The density of the sintered sample was measured by the Archimedes method. The fracture of the sample was observed under the FEI Quanta FEG 450 field emission scanning electron microscope, and the average grain size of the crystal grains was measured by SEM pictures.