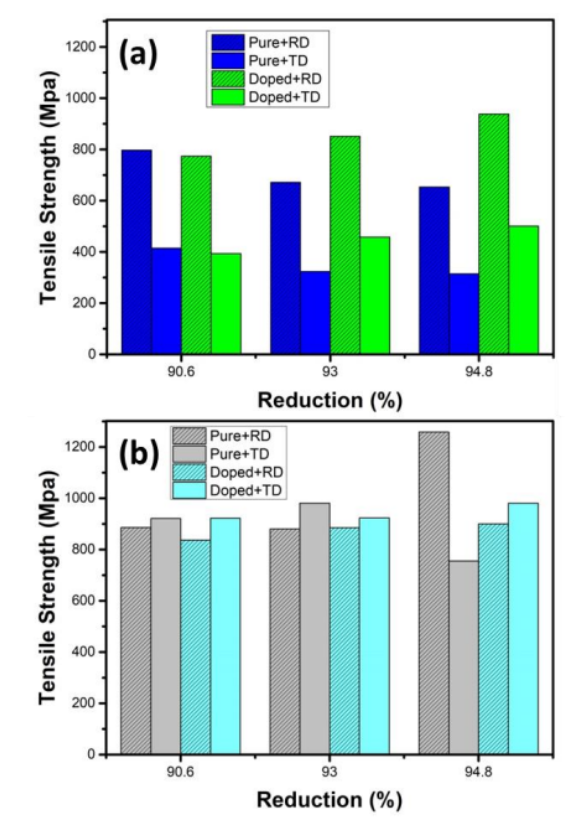

研究两种轧制方式,顺轧和交叉轧对温轧钼板织构和性能的影响,在相同压下量90.6%、93%和94.8%,取两种轧制方式的纯钼板,检测其拉伸性能(分别沿着轧制方向垂直于轧制方向的横向切割拉伸条,表征轧制方向和横向的拉伸性能,观察是否有区别),并用XRD检测方法探究这两种轧制方式对纯钼板织构的组分和含量,探究力学性能和轧制方式以及压下量的关系。

Study the effects of two rolling methods, forward rolling and cross rolling on the texture and performance of warm-rolled molybdenum sheets. At the same reductions of 90.6%, 93% and 94.8%, pure molybdenum sheets with two rolling methods are taken and tested. Its tensile properties (cutting the tensile strips along the rolling direction perpendicular to the rolling direction to characterize the tensile properties of the rolling direction and the transverse direction, and observe whether there is a difference), and use the XRD detection method to explore the two types of rolling The method explores the relationship between the mechanical properties and the rolling method and reduction of the composition and content of the texture of the pure molybdenum sheet.