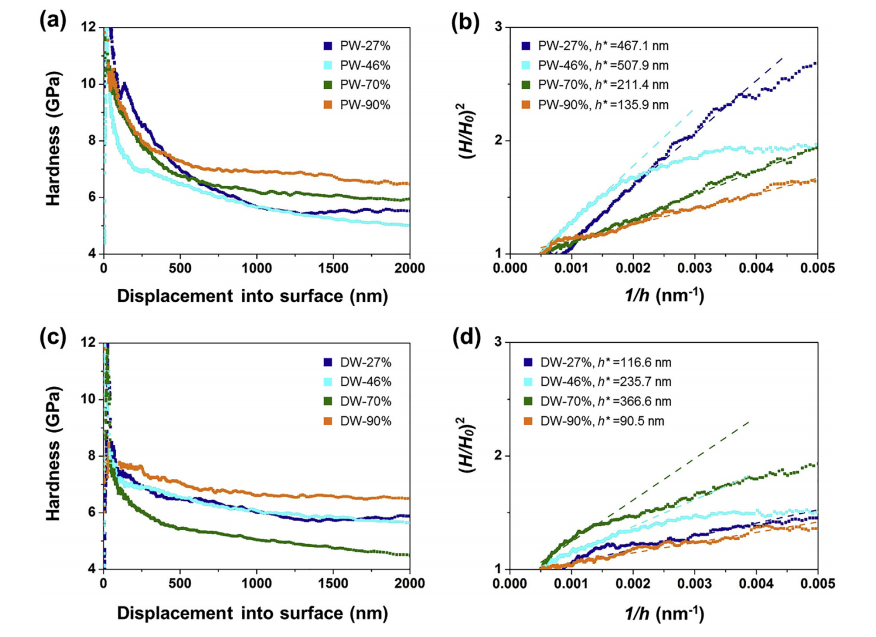

首先采用冷等静压-烧结的方法制备了两种不同纯度的钨板坯(纯钨和掺杂钨),掺杂钨的设计方法是将微量杂质粉末(石墨粉、氧化钨粉、KNO3粉等)混合到商用纯钨粉中。随后进行单向轧制,分别在轧制形变量为27%、46%、70%、90%时进行取样,纯钨样品和掺杂钨样品的制备参数保持完全相同。对于每个轧制压下板,在TD视图(垂直于横向的平面)中进行观察。对EBSD样品进行机械抛光,然后在环境温度下用2.0 wt%NaOH水溶液在5.0 V下进行电解抛光。然后通过HKL Channel 5软件进行晶粒尺寸、织构分析。对每一块样品进行维氏显微硬度测量,施加100 g(0.98 N,HV0.1)的负载,停留时间为15 s。显微硬度值是由10个压痕计算平均值得出。纳米压痕测量(Nano Indenter II,MTS系统)在抛光表面进行,采用连续刚度模式(CSM),最大压痕深度设置为2000 nm,应变速率为0.05/s,泊松比为0.25)。使用CS分析仪(CS844,莱科有限公司)对杂质C和S进行含量分析,使用ONH分析仪(ONH836,莱科有限公司)对杂质O和N进行含量分析,其余杂质元素使用电感耦合等离子体质谱仪(ICP-MS 7700,Aligent有限公司)进行分析。

First, two tungsten slabs with different purity (pure tungsten and doped tungsten) were prepared by the cold isostatic pressing-sintering method. Etc.) mixed into commercial pure tungsten powder. Subsequently, one-way rolling was performed, and sampling was performed when the rolling deformation was 27%, 46%, 70%, and 90%. The preparation parameters of the pure tungsten sample and the doped tungsten sample remained exactly the same. For each rolling reduction plate, observe in the TD view (a plane perpendicular to the transverse direction). The EBSD samples were mechanically polished and then electrolytically polished with 2.0 wt% NaOH aqueous solution at 5.0 V at ambient temperature. Then through HKL Channel 5 software for grain size and texture analysis. The Vickers microhardness measurement was performed on each sample, and a load of 100 g (0.98 N, HV0.1) was applied, and the residence time was 15 s. The microhardness value is calculated from the average of 10 indentations. Nanoindentation measurement (Nano Indenter II, MTS system) is performed on the polished surface, using continuous stiffness mode (CSM), the maximum indentation depth is set to 2000 nm, the strain rate is 0.05/s, and the Poisson's ratio is 0.25). Use CS analyzer (CS844, Lyco Co., Ltd.) to analyze the content of impurities C and S, use ONH analyzer (ONH836, Lyco Co., Ltd.) to analyze the content of impurities O and N, and use inductively coupled plasma for other impurity elements Mass spectrometer (ICP-MS 7700, Aligent Co., Ltd.) for analysis.