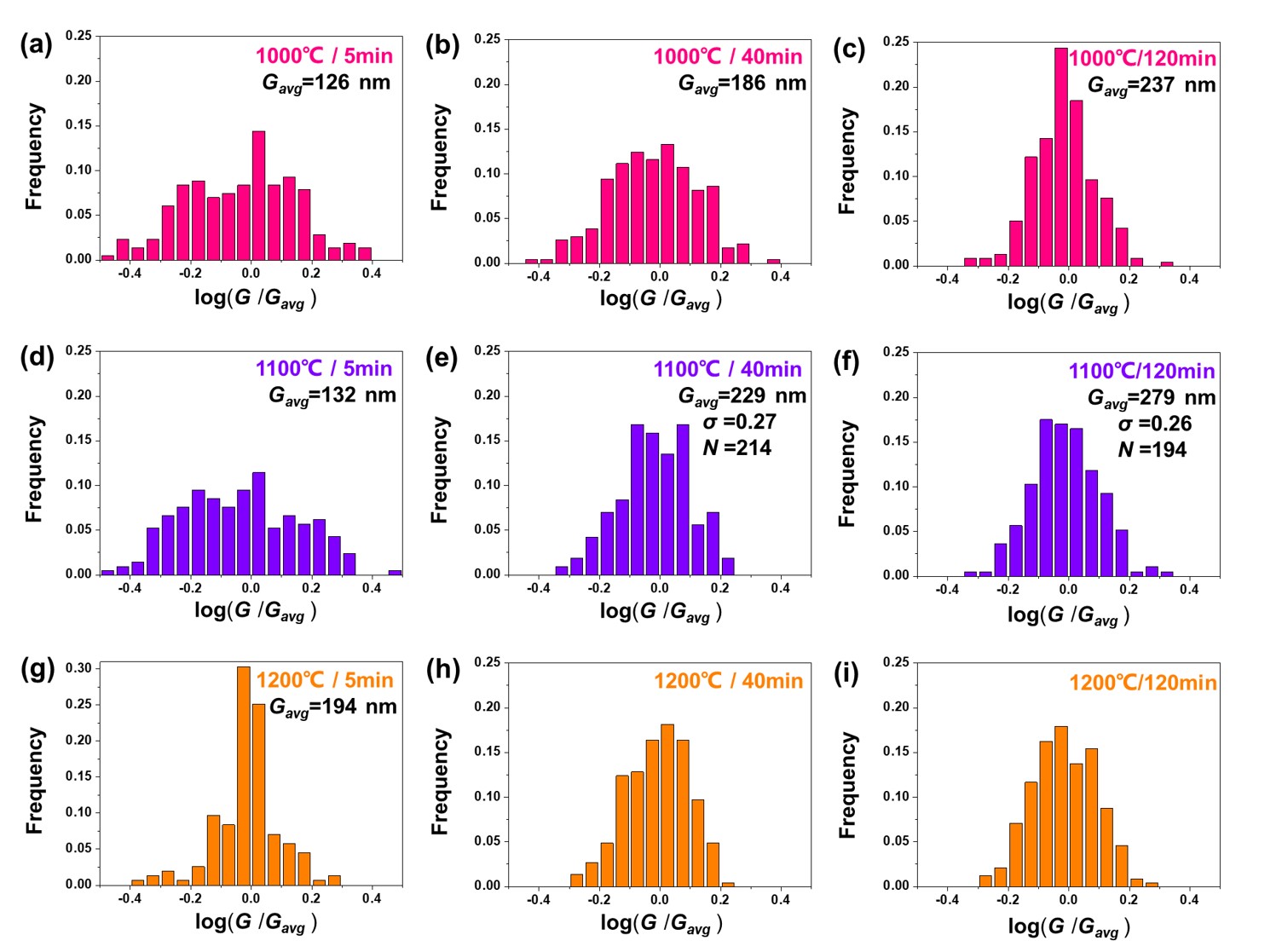

以不同粒径及粒径搭配的钨粉为原料,钨粉通过冷等静压成形得到坯体,坯体在氢气气氛中进行烧结,烧结温度为1300-1500℃,保温时间为1-3小时。测试烧结样品的致密度。扫描和EBSD采集方案:首先对样品表面进行机械研磨和抛光,然后在25%高氯酸和75%的酒精混合溶液中,以10±2 V的电压和45±5 A的电流进行电解抛光,持续时间为120-300 s。通过EDAX配置的电子背散射衍射(EBSD)进行测量,扫描步长设为0.05°,扫描时间为30 min/样。通过样品的SEM显微组织,统计样品的晶粒尺寸。

Using tungsten powder with different particle sizes and particle sizes as raw materials, the tungsten powder is formed by cold isostatic pressing to obtain a green body. The green body is sintered in a hydrogen atmosphere at a sintering temperature of 1300-1500°C and a holding time of 1-3 hours . Test the density of sintered samples. Scanning and EBSD acquisition scheme: firstly, the sample surface is mechanically ground and polished, and then electropolished in a mixed solution of 25% perchloric acid and 75% alcohol at a voltage of 10 ± 2 V and a current of 45 ± 5 A. The duration is 120-300 s. The measurement is carried out by electron backscatter diffraction (EBSD) configured by EDAX, the scanning step is set to 0.05°, and the scanning time is 30 min/sample. Through the SEM microstructure of the sample, the crystal grain size of the sample is counted.