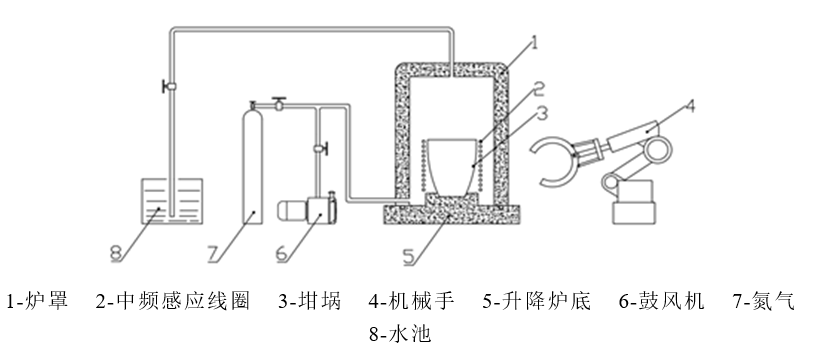

该装置包括带有进料口及进气口的密闭反应系统、通过排烟管道与密闭反应系统内腔相连通的烟尘净化系统、自动浇铸系统、自动升降系统及鼓风系统;密闭反应系统的内表面设置有耐火隔热内衬层,在密闭反应系统内部设置有中频感应线圈,中频感应线圈固定在炉罩上,中频感应线圈与密闭反应系统侧壁之间的距离约250mm,在中频感应线圈内放置有可取换的石墨坩埚,每次放置后需要将坩埚进行固定;在炉罩底部设置有石棉密封圈;烟尘净化系统为水池,排烟管道伸入水池内;自动浇铸系统内含一个机械手,采用机械手取换石墨坩埚和实现自动浇铸;自动升降系统是在炉底放置一个升降机,便于石墨坩埚的取换;鼓风系统包含一个鼓风机,主要用于将密闭反应系统内的P2O5烟尘彻底排入到水池内。

The device comprises a closed reaction system with a feed port and an air inlet, a smoke purification system connected with the inner cavity of the closed reaction system through a smoke exhaust pipe, an automatic casting system, an automatic lifting system and an air blowing system;The inner surface of the sealed reaction system Settings are lining refractory insulating layer, inside the airtight reaction system with medium frequency induction coil, medium frequency induction coil is fixed on the furnace cover, medium frequency induction coil and sealed reaction system, the distance between the side wall is about 250 mm in intermediate frequency induction coil placed within a desirable in the graphite crucible, after each place needs to be fixed crucible;The bottom of the furnace cover is provided with an asbestos sealing ring;The smoke purification system is a pool, and the smoke exhaust pipe reaches into the pool.The automatic casting system includes a manipulator, which is used to take graphite crucible and realize automatic casting.The automatic lifting system is to place a lift at the bottom of the furnace to facilitate the graphite crucible replacement;The blast system consists of a blower which is used to discharge P2O5 fumes from the closed reaction system into the tank.