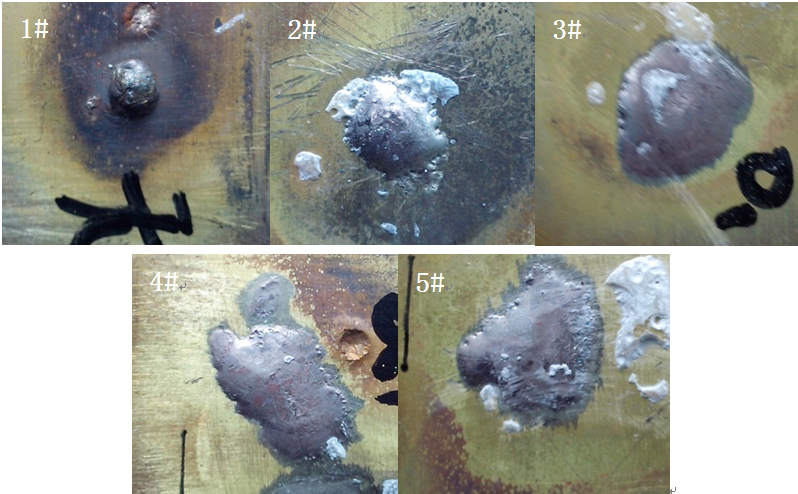

项目选用铜基钎料用铜钎剂1#、2#、3#、4#、5#,在电阻炉内进行铺展性能测试,试验结果如图2.22所示。可以看出,1#铜钎剂粘度大,包裹住钎料使钎料难铺展;2#铜钎剂粘度低、但活性也低,钎料铺展性能稍差;3#、4#、5#铜钎剂的去膜能力较强、活性较好,钎料流铺性较好。考虑到4#、5#铜钎剂氟硼酸盐含量较高,且氟硼酸盐具有潮解性和腐蚀性,因此3#钎剂的综合性能较好,可将其作为铜基钎料用钎剂。

称取BCu89PAg系铜基钎料用钎剂1#、2#、3#、4#、5#,在电阻炉内进行铺展性能测试,试验结果如图2.23所示。可看出,1#铜钎剂去膜能力差,钎料氧化、几乎不铺展;2#铜钎剂具有较弱的去膜能力,其铺展流动性能稍差性;3#、4#、5#铜钎剂的去膜能力较强、活性较好,钎料流铺性较好。同样考虑到4#、5#钎剂中氟硼酸盐含量高,氟硼酸盐具有潮解性和腐蚀性,因此3#钎剂的综合性能较好,可作为BCu89PAg系铜基钎料用钎剂。

The project uses copper fluxes 1#, 2#, 3#, 4#, and 5# for copper-based solder, and conducts the spreading performance test in the resistance furnace. The test results are shown in Figure 2.22. It can be seen that the viscosity of 1# copper flux is high, and it is difficult to spread the solder by wrapping the solder; the viscosity of 2# copper flux is low, but the activity is also low, and the spreading performance of the solder is slightly worse; 3#, 4#, 5# Copper flux has strong film removal ability, good activity, and good solder flowability. Considering the high content of fluoroborate in 4# and 5# copper fluxes, and the deliquescent and corrosive properties of fluoroborate, the 3# flux has better overall performance and can be used as copper-based solder Flux.

Weigh 1#, 2#, 3#, 4#, 5# for BCu89PAg series copper-based brazing filler metal, and conduct a spreading performance test in a resistance furnace. The test results are shown in Figure 2.23. It can be seen that the 1# copper flux has poor film removal ability, and the solder oxidizes and hardly spreads; 2# copper flux has weak film removal ability, and its spreading fluidity is slightly worse; 3#, 4#, 5 #Copper flux has strong film removal ability, good activity, and good solder flowability. Also taking into account the high content of fluoroborate in 4# and 5# fluxes, fluoroborate has deliquescent and corrosive properties, so 3# flux has better overall performance and can be used as a brazing material for BCu89PAg series copper-based solders.