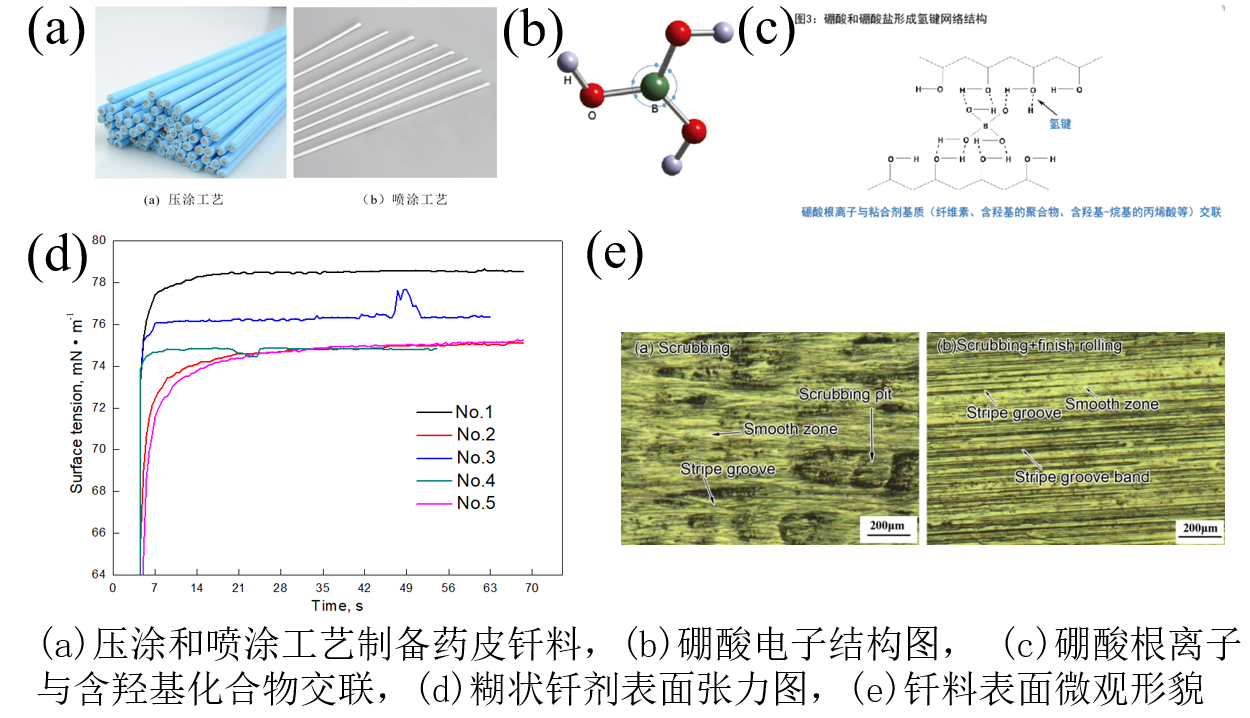

表面张力共测试了5次,硼酸中的硼原子与含有羟基的化合物交联形成氢键结构,这是钎剂产生自粘接的根本原因。研究表明,溶液的表面张力除受温度和压力的影响外,还与其组成有关,即溶质的存在可以影响溶液的表面张力。分别经擦洗、擦洗-精轧两种工序处理后,钎料表面微观形貌有较大的差别。经过擦洗后,钎料表面前道工序的“条纹状”轧制形貌得到大幅度的减弱,表面微结构呈现短而深的“条纹槽”及其两侧大面积的擦洗“平滑区”,同时,表面留下擦洗痕迹,其擦洗坑沿着擦洗反方向拖尾。与单纯经擦洗处理后情况不同,经擦洗+精轧处理的钎料表面微观结构由条纹槽带、条纹槽和组成,“平滑区”位于条纹槽带或条纹槽间,其宽度大小不一,一般大于条纹槽但远小于条纹槽带,条纹槽带由许多大小不一的密集条纹槽组成,大部分“条纹槽”宽而深,宏观表现出钎料表面粗糙度增大。擦洗+精轧处理后钎料表面黏附钎剂层分布较均匀,钎剂液收缩坑较少,且具有较大的单位面积钎料表面黏附钎剂液质量。擦洗处理后钎料表面原有的条纹槽和条纹槽带被擦平或擦浅,呈现出大面积的擦洗“平滑带”,钎剂液收缩坑较多且面积较大,具有相对较小的单位面积钎料表面黏附钎剂液质量。

The surface tension was tested 5 times in total,the boron atom in boric acid crosslinks with the compound containing hydroxyl to form a hydrogen bond structure, which is the fundamental reason for the self-adhesion of the flux. Studies have shown that the surface tension of a solution is not only affected by temperature and pressure, but also related to its composition, that is, the presence of solutes can affect the surface tension of the solution. After the two processes of scrubbing, scrubbing and finishing rolling, the microscopic morphology of the solder surface is quite different. After scrubbing, the "stripe" rolling morphology of the previous process on the surface of the solder is greatly weakened, and the surface microstructure presents short and deep "stripe grooves" and large areas of scrubbing "smooth areas" on both sides. At the same time, a scrubbing trace is left on the surface, and the scrubbing pit trails in the opposite direction of scrubbing. Different from the situation after only scrubbing, the surface microstructure of the solder after scrubbing + finishing is composed of striped grooves, striped grooves, and striped grooves. The "smooth zone" is located in the striped grooves or between the striped grooves, and its width varies. Generally larger than the striped groove but much smaller than the striped groove. The striped groove is composed of many dense striped grooves of different sizes. Most of the "striped grooves" are wide and deep, and the surface roughness of the solder is increased macroscopically. After scrubbing + finishing rolling, the solder surface adhesion flux layer is distributed more uniformly, the flux shrinkage pits are less, and the unit area solder surface adhesion flux liquid quality is larger. After the scrubbing treatment, the original striped grooves and striped grooves on the surface of the solder are smoothed or shallow, showing a large area of scrubbing "smooth band". The flux shrinkage pits are large and the area is relatively small. The quality of the flux liquid adhered to the surface of the solder per unit area.