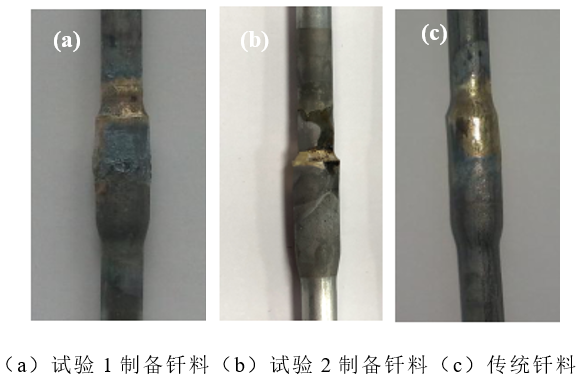

试验1为使用ARPVB(聚乙烯醇缩丁醛)+乙醇作为钎剂,试验2为使用乙醇作为钎剂。

含有粘接剂的药皮钎料钎焊后残渣较多,其原因为钎焊过程中粘接剂受热分解、碳化,产生大量有害气体,不仅污染环境,还损害操作员的身体健康,非常不环保;同时在钎缝中产生夹杂,降低钎焊可靠性。项目研发的产品不含有机胶粘剂,符合RoHS标准,钎焊燃烧时大大减轻了对环境的污染,进而保护了操作员的身体健康;与传统钎料相比,不存在钎料乱流现象,节约钎料和钎剂的用量。

Test 1 used ARPVB (polyvinyl butyral) + ethanol as the flux, and test 2 used ethanol as the flux.

The coating solder containing adhesive has more residues after brazing. The reason is that the adhesive is thermally decomposed and carbonized during the brazing process, and a large amount of harmful gas is generated, which not only pollutes the environment, but also damages the health of the operator. Environmental protection; At the same time, inclusions are generated in the brazing seam, reducing the reliability of brazing. The products developed by the project do not contain organic adhesives and comply with RoHS standards. When brazing is burned, the pollution to the environment is greatly reduced, thereby protecting the health of the operators; compared with traditional brazing materials, there is no turbulent flow of brazing materials and saving The amount of solder and flux.