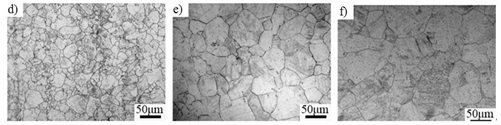

图(d)(e)(f)分别为DZ2(0.17V0Nb)钢加热至850℃、900℃和950℃,保温1h,得到试验钢的奥氏体晶粒形貌图,由图可知,DZ2(0.17V0Nb)钢的奥氏体晶粒均为等轴的晶粒,根据直线截距法统计了奥氏体晶粒尺寸可知,DZ2(0.17V0Nb)钢在850℃、900℃和950℃,保温1h后的奥氏体平均晶粒尺寸分别为30 µm、51µm和88 µm,可见随着奥氏体化温度的升高奥氏体晶粒尺寸逐渐增大。对比DZ2(0.04V0Nb)钢可以发现,V的添加可以细化奥氏体晶粒尺寸。

Figure (d), Figure (e) and Figure (f) respectively show the austenite grain morphology of DZ2 (0.17V0Nb) steel after heating to 850℃, 900℃ and 950℃ for 1h. It can be seen from the figure that the austenite grains of DZ2 (0.17V0Nb) steel are equiaaxial grains. According to the straight cut method, the austenite grain size is calculated. The average austenite grain size of DZ2 (0.17v0nb) steel held at 850℃, 900℃ and 950℃ for 1h is 30 µm, 51µm and 88 µm, respectively. It can be seen that the austenite grain size increases gradually with the increase of austenitizing temperature. Compared with DZ2 (0.04V0Nb) steel, it can be found that the addition of V can refine the austenite grain size.