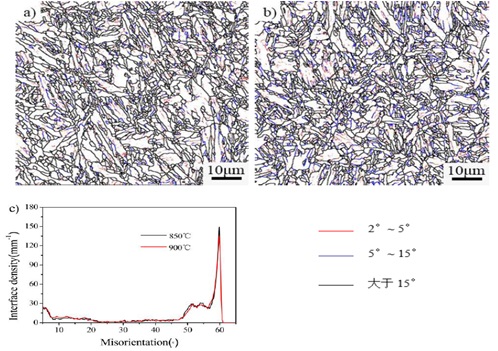

图(a)(b)分别为DZ2(0.18V0.04Nb)钢850℃和900℃保温1h油淬至室温后在675℃回火4h的GB图,经计算,大于15°的大角度界面密度分别为1884 mm-1和1831mm-1;经过测量,在850℃、900℃保温淬火得到的板条块宽度分别为1.4µm和1.7µm。可见850℃淬火的试验钢的板条块宽度更小。图(c)为DZ2(0.18V0.04Nb)钢在850℃、900℃保温两种热处理工艺下的界面密度—取向差分布图。由图可知,DZ2(0.18V0.04Nb)钢在850℃保温1h后675℃回火4h的试验钢中有更高的大角度界面。由以上分析可知,0.17V和0.18V-0.04Nb钢组织变化规律与0.05V钢基本一致,合金钢中提高V含量和添加微量Nb均会进一步细化组织,但细化板条块宽度的程度要小于细化原奥氏体晶粒的程度。

Figure (a) and (b) are GB figures of DZ2 (0.18V0.04Nb) steel held at 850℃ and 900℃ for 1h after oil quenching to room temperature and tempered at 675℃ for 4h. After calculation, the large-angle interface densities greater than 15° are 1884 mm-1 and 1831mm-1, respectively. After measurement, the width of the lath obtained at 850℃ and 900℃ is 1.4µm and 1.7µm, respectively. It can be seen that the width of the strip block of the test steel quenched at 850℃ is smaller. Figure (c) shows the distribution of interface density-orientation difference of DZ2 (0.18V0.04Nb) steel under 850℃ and 900℃ heat treatment. It can be seen from the figure that DZ2 (0.18V0.04Nb) steel has higher large-angle interface in the test steel after holding at 850℃ for 1h and tempering at 675℃ for 4h. From the above analysis, it can be seen that the microstructure change of 0.17V and 0.18V-0.04Nb steel is basically the same as that of 0.05V steel. Increasing THE CONTENT of V and adding trace Nb in alloy steel will further refine the microstructure, but the extent of refining the lat width is less than that of refining the original austenite grain.