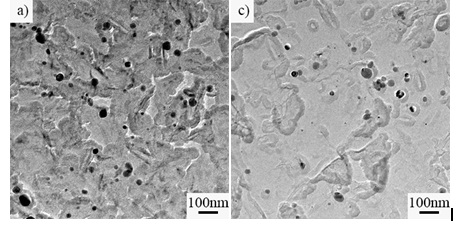

图(a)和(c)分别为DZ2(0.17V0Nb)钢在850℃和950 ℃下保温1 h后,基体中存在少数尺寸较大的圆球形第二相颗粒,这些大尺寸第二相主要是在均热及轧制过程中析出;除此之外,基体中还存在较多粒径较小的球形和椭球形第二相颗粒,而这些第二相颗粒主要是在再加热奥氏体化过程中析出。通过直线截距法统计析出物尺寸可知,DZ2(0.17V0Nb)钢在850℃和950 ℃下保温1 h后析出物平均尺寸分别为20 nm和29 nm。

After DZ2 (0.17V0Nb) steel was held at 850℃ and 950 ℃ for 1 h, a small number of large spherical second phase particles existed in the matrix, and these large second phase particles were mainly precipitated during soaking and rolling process. In addition, there are many spherical and ellipsoidal second phase particles with smaller particle size in the matrix, and these second phase particles are mainly precipitated during the reheating austenitizing process. The average precipitate size of DZ2 (0.17V0Nb) steel is 20 nm and 29 nm after holding at 850℃ and 950 ℃ for 1 h, respectively.