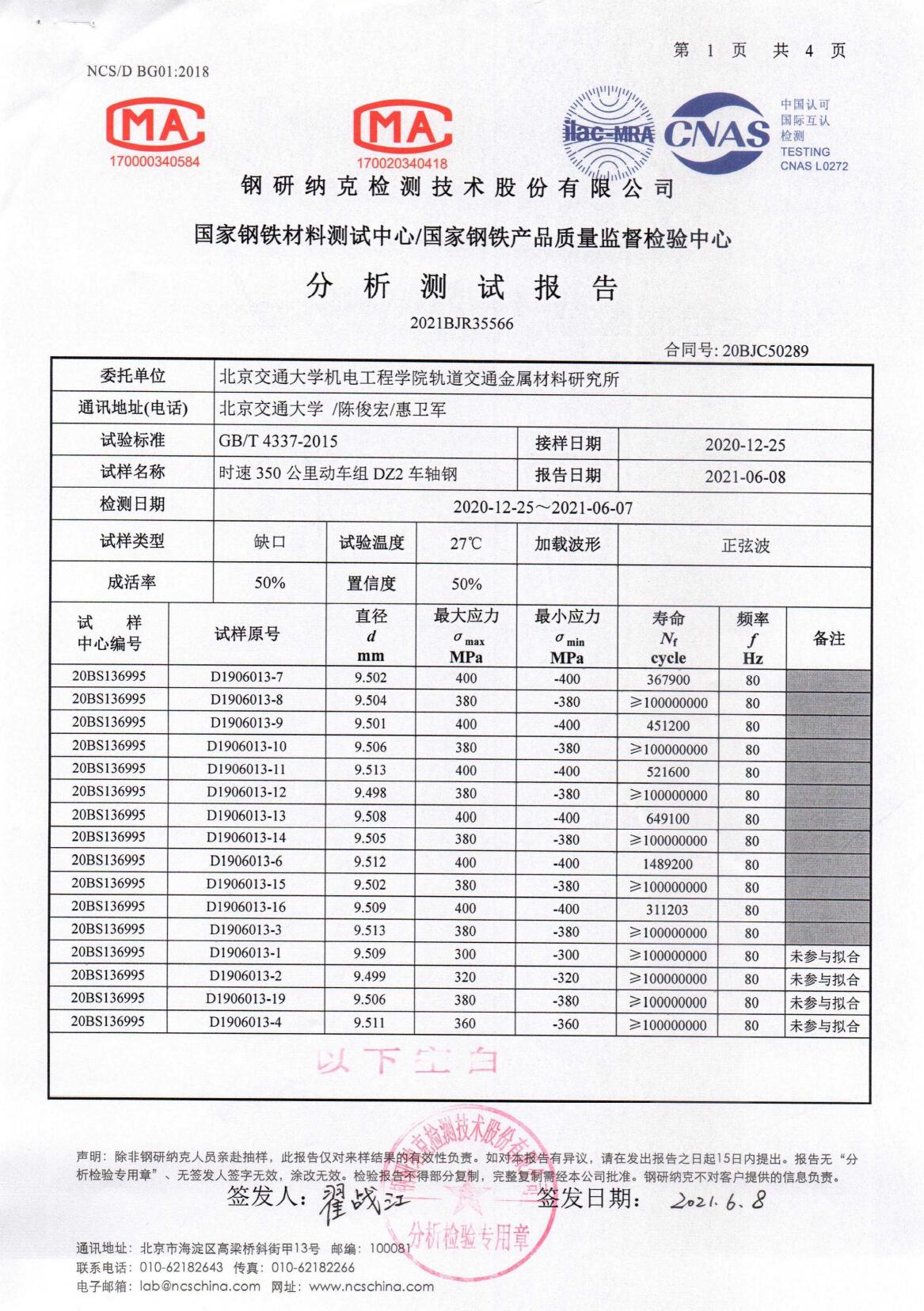

疲劳性能测试参考GB/T 4337-2015进行试验,在微机控制高频疲劳试验机-QBG-100上开展实验,加载频率为 80 Hz。为了减小疲劳试样在试验过程中内摩擦导致的发热效应,本实验采用压缩空气对试样进行冷却,并采用150ns间隙加载。利用升降法得到疲劳试验的散点图,绘制S-N曲线,继而测得试验钢的疲劳极限。

The fatigue performance test was carried out according to GB/T 4337-2015. The test was carried out on the microcomputer controlled high frequency fatigue testing machine -QBG-100, and the loading frequency was 80 Hz. In order to reduce the heating effect caused by internal friction in the fatigue sample during the test, compressed air was used to cool the sample and 150ns clearance loading was used. Scatter diagram of fatigue test was obtained by lifting method, s-N curve was drawn, and then the fatigue limit of test steel was measured.