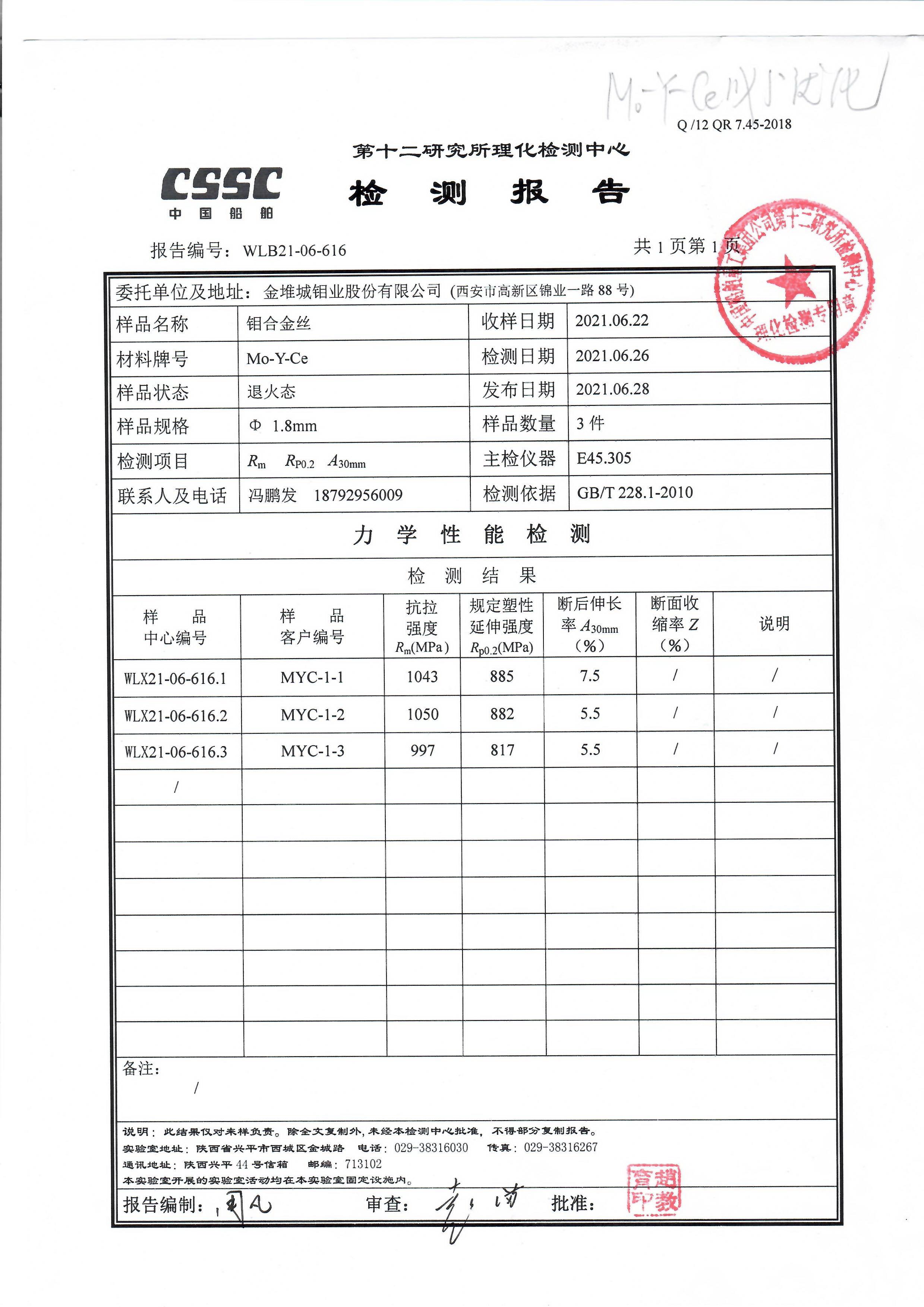

在Mo-0.6Y2O3合金的基础上,以0.03%CeO2、0.06%CeO2、0.08%CeO2、0.12%CeO2、0.15%CeO2五种不同含量,烧结,锻造、拉拔至Ø0.18mm的丝材。在拉拔过程中,五种Mo-Y-Ce合金均在Ø1.8mm取样,测量室温力学性能,并对中间产品和Ø1.8mm丝最终产品Ø0.18mm丝进行断口分析。

On the basis of Mo-0.6Y2O3 alloy, with 0.03% CeO2, 0.06% CeO2, 0.08%CeO2, 0.12% CeO2, 0.15%CeO2 five different contents, sintered, forged, and drawn to Ø0.18mm wire.During the drawing process, the five Mo-Y-Ce alloys were sampled at Ø1.8mm to measure the mechanical properties at room temperature, and fracture analysis was performed on the intermediate product and the final product of Ø1.8mm wire with Ø0.18mm wire.