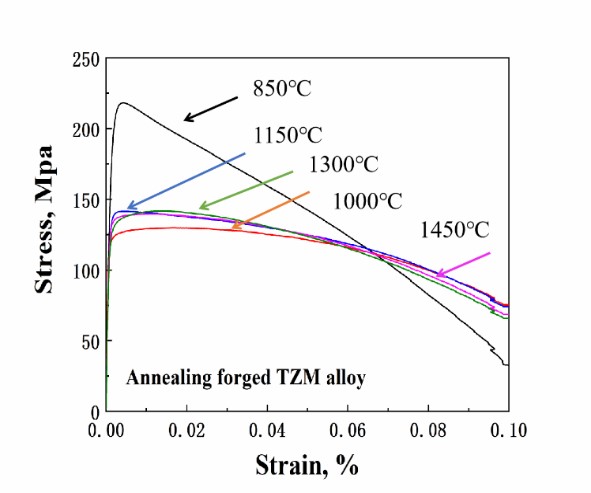

原材料选取两种加工态TZM合金(锻造态和轧制态),由安泰科技股份有限公司提供。电火花线切割成特定试样尺寸,对其进行超声清洗等处理。将制备的试样在氢气炉中进行去应力退火,退火温度为850°C~1450°C。然后对退火前后的试样拉伸,拉伸速率为5 mm/min;压缩试验在WDW300型万能试验机上对锻态和轧态TZM合金进行退火前后压缩变形,退火温度为850°C~1600°C,压缩速率为0.5 mm/min、0.1 mm/min和5 mm/min。拉伸试样由轧制态的厚度为3mm的合金薄板和直径为12mm的锻造态TZM合金棒制成。对锻态TZM合金拉伸样热处理,退火实验在氢气保护气氛条件下进行,分别选取 850℃、1000℃、1150℃、1300℃和1450℃进行退火处理,以60°C/min的速率加热到退火,保温1 h 后冷却至室温,然后分别在1600℃下高温拉伸。在航空航天工艺研究所测试高温拉伸性能,样品的单轴拉伸试验是在3000℃通电加热力学性能试验系统上操作,试验在抽真空后通氩气的条件下通电加热,拉伸速率为5mm/min;室温拉伸试验在西北工业集团进行测试,拉伸机型号为MTS810,进一步分析合金的强塑性以及微观组织结构。压缩变形试样采用以下工艺:退火温度为850℃、1000℃、1150℃、1300℃、1450℃以及1600℃;压缩速率为0.5mm/min、1mm/min以及5mm/min;压缩率均为90%。将压缩变形的圆饼状试样作为研究对象,对变形温度分别为室温、1150℃退火以及1450℃退火,应变速率为1mm/min和5mm/min进行宏观形貌分析,对其中的室温、1300℃退火、1600℃退火,应变速率为0.5mm/min和5mm/min的微观组织和织构进行EBSD研究。

Two processed TZM alloys (forged and rolled) were selected as raw Materials, which were provided by Advanced Technology & Materials Co., Ltd. Edm wire-cut to a specific sample size, ultrasonic cleaning and other processing. The prepared samples were stress-relieved annealed in a hydrogen furnace at 850°C ~ 1450°C. Then the specimens before and after annealing were stretched at a rate of 5 mm/min. The compressive deformation of forged and rolled TZM alloys before and after annealing was performed on WDW300 universal testing machine. The annealing temperature was 850°C ~ 1600°C, and the compression rates were 0.5 mm/min, 0.1 mm/min and 5 mm/min. The tensile specimen is made of rolled alloy sheet with a thickness of 3mm and forged TZM alloy bar with a diameter of 12mm. The tensile samples of forged TZM alloy were heat treated, and the annealing experiments were carried out in hydrogen protected atmosphere. They were annealing at 850℃, 1000℃, 1150℃, 1300℃ and 1450℃, respectively, and heated to annealing at 60°C/min. After holding for 1 h, they were cooled to room temperature, and then stretched at 1600℃. The high temperature tensile properties of the samples were tested in the institute of aerospace technology. The uniaxial tensile test of the samples was carried out on the mechanical properties test system under electric heating at 3000℃. The tensile rate was 5mm/min under electric heating under the condition of argon gas after vacuum pumping. The tensile test at room temperature was carried out in Northwest Industrial Group, and the tensile model was MTS810. The strong plasticity and microstructure of the alloy were further analyzed. The compressive deformation samples were processed as follows: annealing temperatures were 850℃, 1000℃, 1150℃, 1300℃, 1450℃ and 1600℃; The compression rate is 0.5mm/min, 1mm/min and 5mm/min. The compression rate is 90%. The deformation temperature is room temperature, 1150℃ annealing and 1450℃ annealing respectively, and the strain rate is 1mm/min and 5mm/min for macro morphology analysis. The deformation temperature, 1300℃ annealing, 1600℃ annealing, The microstructure and texture at strain rates of 0.5mm/min and 5mm/min were studied by EBSD.