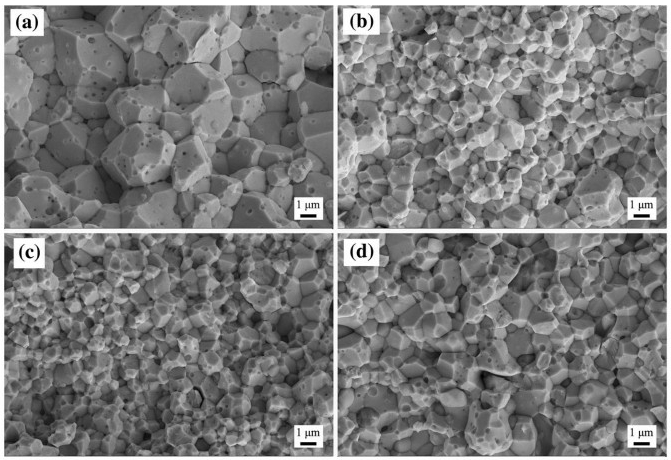

以溶液燃烧结合氢还原制备的掺杂钨粉。偏钨酸铵、硝酸铵、甘氨酸的浓度分别为0.01 M、0.24 M和0.1 M,硝酸镧的浓度分别为0 M、0.00068 M、0.00136 M、0.00275 M和0.00714 M以制备氧化镧掺杂量分别为0wt%、0.5 wt %、1 wt %、2 wt %、5 wt %的样品(分别标为PW、WL05、WL10、WL20、WL50)。偏钨酸铵原料首先溶解在去离子水中,将所制备的溶液加热,直到燃烧得泡沫混合物,随后研磨,在流动氢气中还原2小时,0wt%、0.5 wt %、1 wt %、2 wt %、5 wt %的样品还原温度分别为700 ℃, 700℃, 700℃, 750℃和850℃,得到掺杂钨粉末。在700 MPa的单轴压力下压成坯体,然后在钨丝炉中在氢气流动下烧结。0wt%、0.5 wt %、1 wt %、2 wt %、5 wt %的样品烧结温度分别为1500℃、1500℃、1500℃、1650℃、1650℃,烧结时间2小时,升温速率5℃/min。

Doped tungsten powder prepared by solution combustion combined with hydrogen reduction. The concentrations of ammonium metatungstate, ammonium nitrate, and glycine were 0.01 M, 0.24 M, and 0.1 M, respectively, and the concentrations of lanthanum nitrate were 0 M, 0.00068 M, 0.00136 M, 0.00275 M, and 0.00714 M to prepare the doped amounts of lanthanum oxide. The samples are 0wt%, 0.5wt%, 1wt%, 2wt%, 5wt% (labeled PW, WL05, WL10, WL20, WL50, respectively). Ammonium metatungstate raw material is first dissolved in deionized water, the prepared solution is heated until the foam mixture is burned, and then ground, and reduced in flowing hydrogen for 2 hours, 0wt%, 0.5wt%, 1wt%, 2wt% The reduction temperature of the 5 wt% sample is 700 ℃, 700 ℃, 700 ℃, 750 ℃ and 850 ℃, respectively, to obtain doped tungsten powder. It is pressed into a green body under a uniaxial pressure of 700 MPa, and then sintered in a tungsten wire furnace under hydrogen flow. The sintering temperature of 0wt%, 0.5 wt%, 1 wt%, 2 wt%, and 5 wt% samples are respectively 1500℃, 1500℃, 1500℃, 1650℃, 1650℃, the sintering time is 2 hours, the heating rate is 5℃/min .