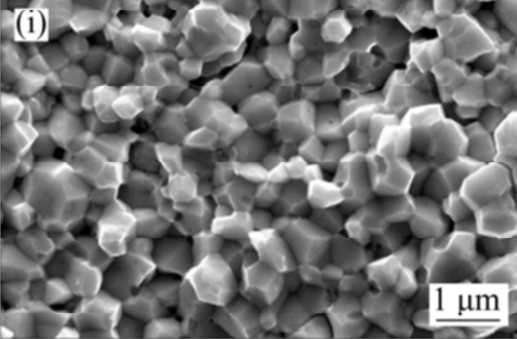

通过对具有三种不同掺杂路线(液-液(WL10)、液-固(WLNO)和固-固(WLO))的纳米级粉末进行扫描电镜观测。通过观察发现烧结后,WLO样品的平均晶粒尺寸大于WL10和WLNO样品。通过与 WLNO 和 WLO 样品相比,WL10 样品在 1500 °C 烧结后获得了优化后的粒径最小的 La2O3 颗粒,颗粒均匀分布在晶界或晶粒内部。与传统制造的钨材料相比,该研究通过液-液掺杂途径展示了超细微观结构。

The nano powders with three different doping routes (liquid-liquid (WL10), liquid-solid (WLNO) and solid-solid (WLO) and different sintering temperatures were observed by scanning electron microscopy. It was observed that the average grain size of WLO samples was larger than that of WL10 and WLNO samples after sintering. Compared with WLNO and WLO samples, WL10 samples were sintered at 1500 °C to obtain optimized La2O3 particles with the smallest particle size, which were evenly distributed at grain boundaries or inside grains. Compared to traditionally manufactured tungsten materials, the study demonstrated ultrafine microstructure through liquid-liquid doping.