以W粉和Fe粉为原料,采用激光金属沉积制备W-Fe复合材料。打印过程中通N2保护,N2流量为5 L/min。所有打印的W-Fe样品被制成固体矩形形状,规格为40毫米× 20毫米。采用LMD参数制备最佳W-Fe复合材料:激光光斑直径3.5 mm;激光功率1000-1600 W;扫描速度300 - 600mm /s;扫描开口间距0.8-1.3 mm;和层厚0.4-0.7 mm。对打印的W-Fe试样进行线切割来评估它们的截面微观结构。采用扫描电镜(SEM)对样品组织、元素进行表征分析,选择区电子衍射(SAED)、扫描TEM (STEM)、同时进行EDS和HRTEM检查。利用聚焦离子束制备透射电镜样品技术(FEI Strata 400S)。

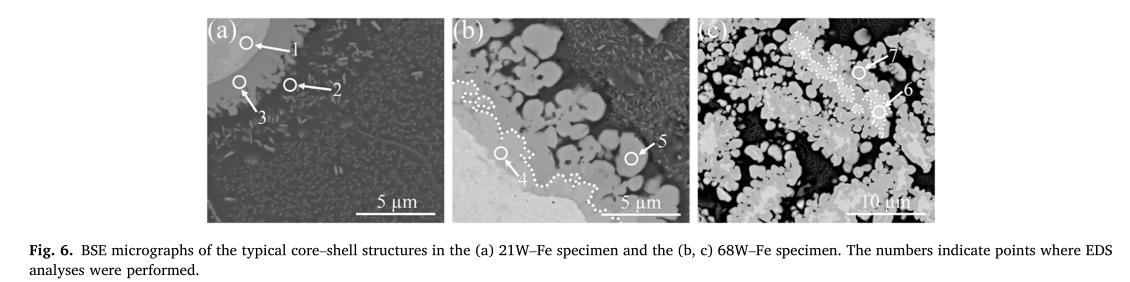

W-Fe composites were prepared by laser metal deposition using W and Fe powders as raw materials. The printing process was protected by passing N2 at a flow rate of 5 L/min. all printed W-Fe samples were made into solid rectangular shapes with a size of 40 mm × 20 mm. The optimal W-Fe composites were prepared using LMD parameters: laser spot diameter 3.5 mm; laser power 1000-1600 W; scanning speed 300-600 mm/s; scanning opening spacing 0.8-1.3 mm; and layer thickness 0.4-0.7 mm. The printed W-Fe specimens were wire cut to evaluate their cross-sectional microstructure. The samples were characterized and analyzed by scanning electron microscopy (SEM) for tissue and elements, selected area electron diffraction (SAED), scanning TEM (STEM), and simultaneous EDS and HRTEM examinations. Transmission electron microscopy sample preparation technique (FEI Strata 400S) using focused ion beam.