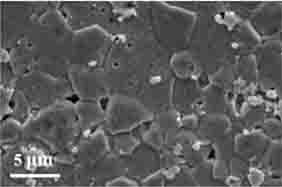

试验以机械混料、氢气两步还原的钼粉和氧化镧颗粒的混合粉末分别进行氢气烧结和 SPS 烧结。将烧结坯表面打磨抛光,去除杂质,用排水法测量试样密度, 硬度用HVS-1000型显微硬度计测量,均匀取5点,去除最高值和最低值后取均值。烧结试样经过预磨,抛光,腐蚀(2.3 g NaOH + 2.6 g K3[Fe(CN)6] + 20 mL H2O)后,用金相显微镜和FESEM型扫描电镜观察组织形貌。

The test was carried out by hydrogen sintering and SPS sintering with a mixture of molybdenum powder and lanthanum oxide particles reduced by mechanical mixing and hydrogen in two steps. The surface of the sintered billet was polished to remove impurities, and the density of the specimen was measured by the drainage method, and the hardness was measured by HVS-1000 micro hardness tester with 5 points evenly taken, and the average value was taken after removing the highest and lowest values. The sintered specimens were pre-polished, polished and etched (2.3 g NaOH + 2.6 g K3[Fe(CN)6] + 20 mL H2O)), and then observed by metallographic microscope and FESEM type scanning electron microscope.