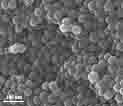

烧结坯打磨抛光后进行腐蚀,分析不同样品的硬度、金相组织、SEM、TEM图像;XRD采集方案:对合金粉末进行物相成分分析,XRD试验电压为40 KV,步长为8°/min,测试范围为10-90°。烧结坯密度采集方案:密度测试采用的仪器为MZ-Q300型高精度粉末冶金比重仪,通过阿基米德排水法原理可推出Mo及Mo-La烧结体的实际密度和相对密度。烧结坯维氏硬度采集方案:采用HVS-10型显微硬度计,在测试前将试样磨平并抛光,并保证样品上下表面平行,所有的测试压力为0.3 kg,保压时间为10 s。力学性能检测:在来自美国英斯特朗公司的双立柱台式材料试验机上对烧结坯料进行室温拉伸试验以及室温压缩试验,室温下压头加载速度为1 mm⸱min-1。

Sintered billets are polished and corroded, and the hardness, metallographic organization, SEM and TEM images of different samples are analyzed; XRD acquisition scheme: the physical composition of the alloy powder is analyzed, the XRD test voltage is 40 KV, the step size is 8°/min, and the test range is 10-90°. Sintered billet density acquisition program: The instrument used for density testing is MZ-Q300 high-precision powder metallurgy specific gravity meter, which can launch the actual density and relative density of Mo and Mo-La sintered body by Archimedes drainage principle. Sintered billet Vickers hardness acquisition scheme: HVS-10 micro hardness tester was used, the specimens were ground and polished before testing, and the upper and lower surfaces of the samples were ensured to be parallel, all the test pressures were 0.3 kg, and the holding time was 10 s. Mechanical property testing: Room temperature tensile test and room temperature compression test were performed on the sintered billet on a double column benchtop material testing machine from Ingstrom, USA, and the room temperature The loading speed of the indenter was 1 mm⸱min-1 at room temperature.