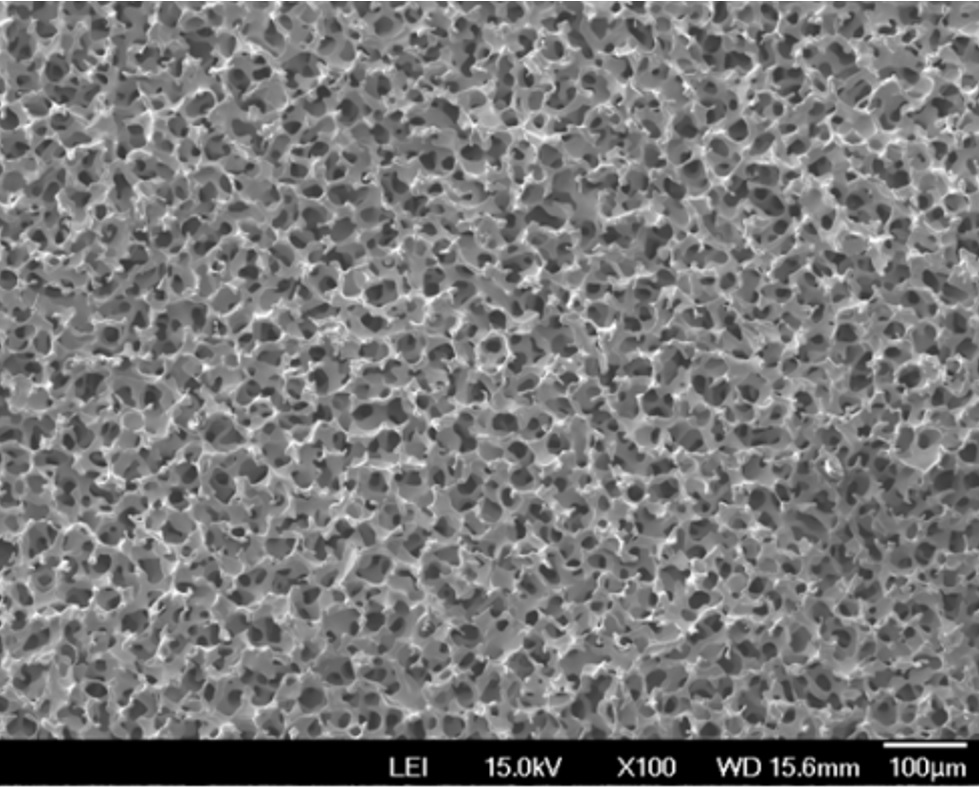

对蓝宝石单晶炉内胆钼片高温蒸发后的样品进行SEM观察,对高温使用后的钨片进行金相组织分析。金相组织采集方案:试样经过机械磨削和抛光成平整、光亮、无磨痕或抛光划痕的镜面,采用10-20%的氢氧化钠+铁氰化钾混合液(氢氧化钠与铁氰化钾质量比为1:1)对样品进行腐蚀,腐蚀后的样品在金相显微镜下放大100×或200×进行组织观察。SEM采集方案:将粉末样品洒在导电胶带,将样品放进样品室中抽真空,调整相应的工作距离光斑和工作电压,把标样的标记线调到荧光屏的中心,聚焦后照相。

The samples of molybdenum sheets in the sapphire single crystal furnace after high-temperature evaporation were observed by SEM, and the metallographic structure of the tungsten sheets after high-temperature use was analyzed. Metallographic structure collection plan: The sample is mechanically ground and polished into a smooth, bright, and non-abrasive or polished mirror surface, using a 10-20% sodium hydroxide + potassium ferricyanide mixture (sodium hydroxide and potassium ferricyanide) The mass ratio of potassium ferricyanide is 1:1) The sample is corroded, and the corroded sample is magnified 100× or 200× under a metallurgical microscope for organization observation. SEM collection scheme: Sprinkle the powder sample on the conductive tape, put the sample into the sample chamber and vacuum, adjust the corresponding working distance spot and working voltage, adjust the mark line of the standard sample to the center of the fluorescent screen, and take a picture after focusing.