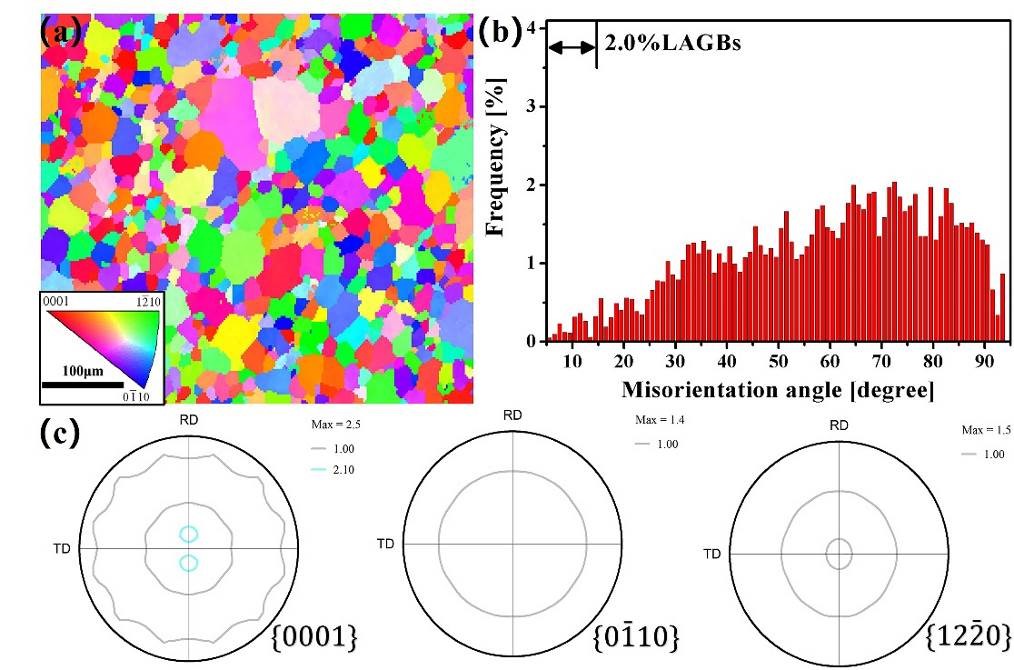

高纯铼坯以纯度>99.99wt%的铼粉为原料,经过预处理、冷等静压及高温烧结(2200℃)。纯铼板坯开坯厚度为 3.1mm,单向轧制,轧至厚度为1.2mm,换向轧至0.3mm。轧制过程中,在形变量为 0%、10%、23%、40%、60%、80%、90%时进行取样。通过金相光学显微镜对不同变形量(10%,24%,60%)的冷轧板材观察。为分析形变过程中的织构演变过程,利用 XRD 测量不同变形量下纯铼板坯的宏观织构。

The high-purity rhenium billet uses rhenium powder with a purity of >99.99wt% as the raw material, and undergoes pretreatment, cold isostatic pressing and high-temperature sintering (2200℃). The thickness of the pure rhenium slab is 3.1mm, and it is rolled to a thickness of 1.2mm in one-way rolling, and rolled to a thickness of 0.3mm in a reverse direction. During the rolling process, sampling is performed when the deformation amount is 0%, 10%, 23%, 40%, 60%, 80%, and 90%. Observe cold-rolled plates with different deformations (10%, 24%, 60%) through a metallographic optical microscope. In order to analyze the texture evolution process in the deformation process, XRD was used to measure the macro texture of the pure rhenium slab under different deformations.