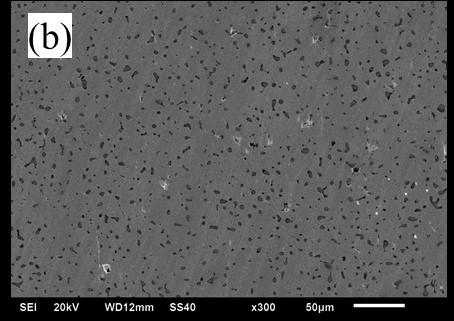

采用对喷式气流磨装置对商业钨粉(费氏粒度为5 μm,纯度>99.9%)进行处理。以氮气为研磨介质,设定研磨腔压力为0.7 MPa,在分选轮的频率为10~50 Hz的范围内对原料钨粉进行改性处理。然后对不同分选轮频率处理而得的钨粉进行粒度搭配,以获得不同粒度分布的粉末,设置了四种批次粉末进行对照实验。分别对四种批次钨粉进行冷等静压-中频感应烧结,四种批次钨粉的压制烧结实验全程在相同条件下完成。利用 SUPRA 55 场发射扫描电镜观察粉末形貌以及烧结态显微组织和孔隙分布。

A counter-jet jet mill is used to process commercial tungsten powder (the Fisher particle size is 5 μm, and the purity is >99.9%). Nitrogen is used as the grinding medium, the pressure of the grinding chamber is set to 0.7 MPa, and the raw tungsten powder is modified within the frequency of the sorting wheel within the range of 10-50 Hz. Then, the tungsten powders processed by different sorting wheel frequencies were matched in particle size to obtain powders with different particle size distributions. Four batches of powder were set up for comparison experiments. Four batches of tungsten powder were subjected to cold isostatic pressing-medium frequency induction sintering, and the entire process of pressing and sintering the four batches of tungsten powder was completed under the same conditions. Use the SUPRA 55 field emission scan Scanning electron microscope (SEM) observes powder morphology, sintered microstructure and pore distribution.